Magnetic field shielding plate M6L-64 | 59 x 40 cm | six-layered, laminated, and highly resistant

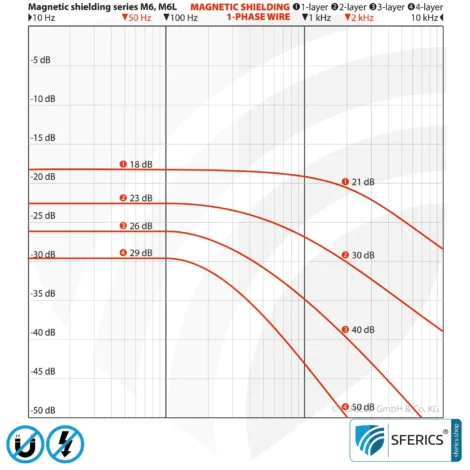

M6L-64 Shielding Plate 59×40 cm: 20-33 dB magnetic field protection at 50 Hz. Ideal for home, office, industry, and vehicles. Robust and easy to process.

Delivery time: approx. 1-3 working days | Base price € 148,75/sqm

€ 35,70 (€ 30,00 excl. VAT)

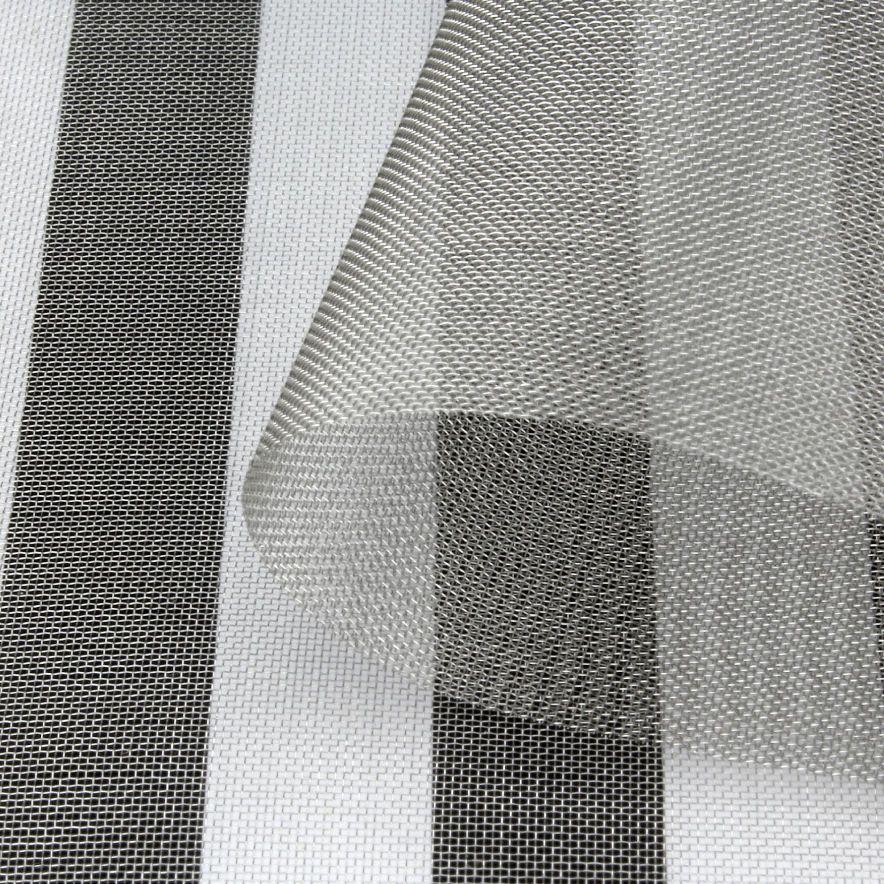

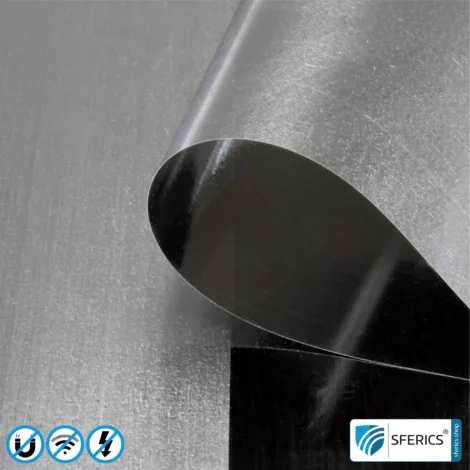

M6L-64 magnetic field shielding plate for shielding low-frequency magnetic fields, size 59 x 40 cm. Highly resistant and extremely flexible in application due to high-quality lamination, e.g., as a shielding intermediate layer in roof and floor structures or in electric vehicles.

The M6L-64 magnetic field shielding plate provides effective protection against low-frequency magnetic fields with a shielding attenuation of 20-33 dB at 50 Hz. Measuring 59 x 40 cm (shielding surface) and an overall size of 61 x 41 cm, it is ideal for use in living spaces, offices, or industrial facilities.

This shielding plate consists of six ultra-thin shielding foils, protected from environmental influences by lamination film – perfect for durable applications such as under floor structures or on flat roofs.

It is suitable for both small areas in the household and large-scale shielding in construction, commercial settings, or vehicles like electric cars and motorhomes.

Applications of the M6L Series

Suitable for both small areas in domestic environments and large areas in construction, commercial, or industrial settings.

Additionally, there are versatile applications in cars, electric vehicles, delivery vans, motorhomes, and caravans.

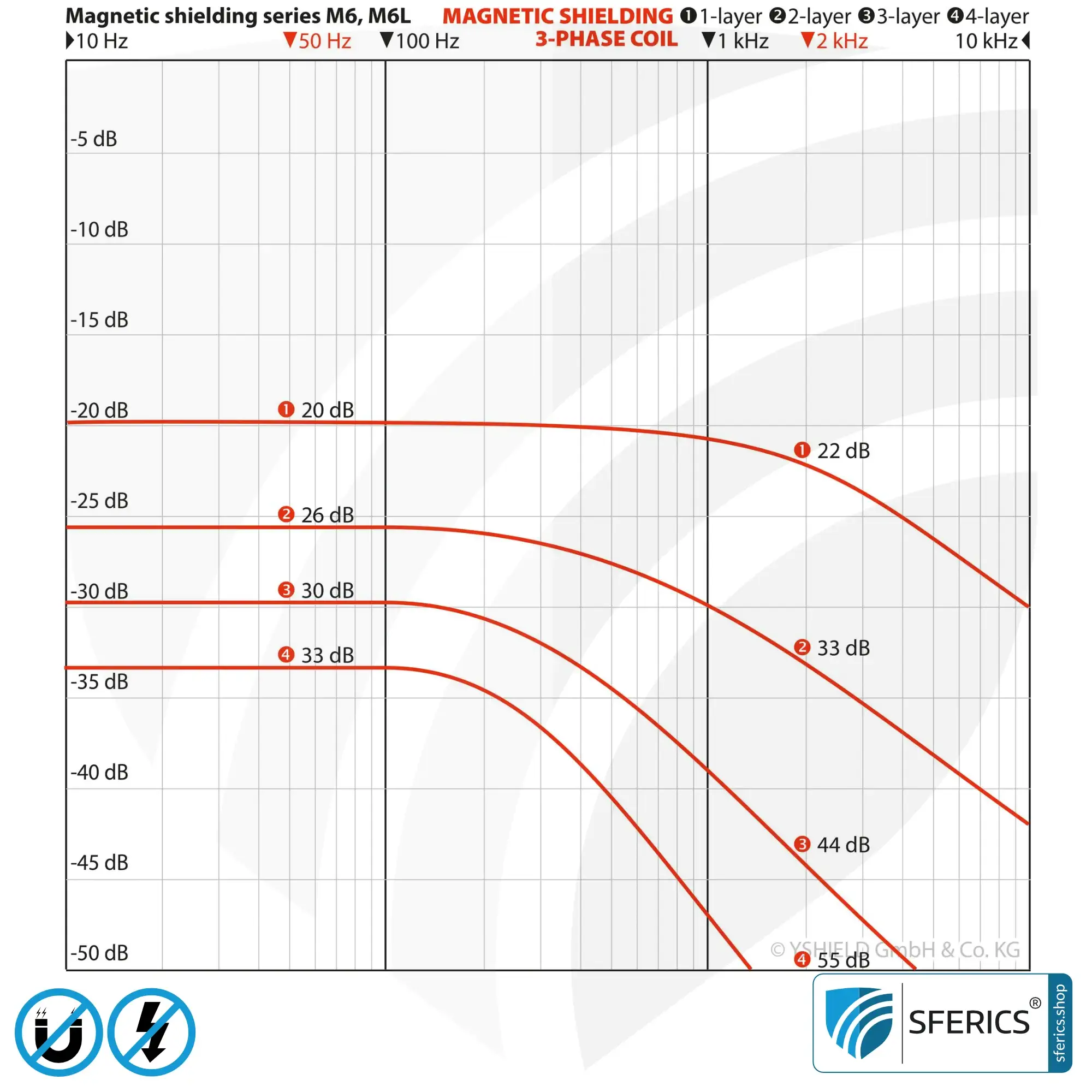

- High Shielding Performance: Up to 33 dB shielding against magnetic fields – a single plate is sufficient for simple applications, while multiple layers of plates can be used for strong fields.

- Easy Processing: Easy handling with scissors, glue, or a stapler, along with the option for grounding, makes it universally applicable.

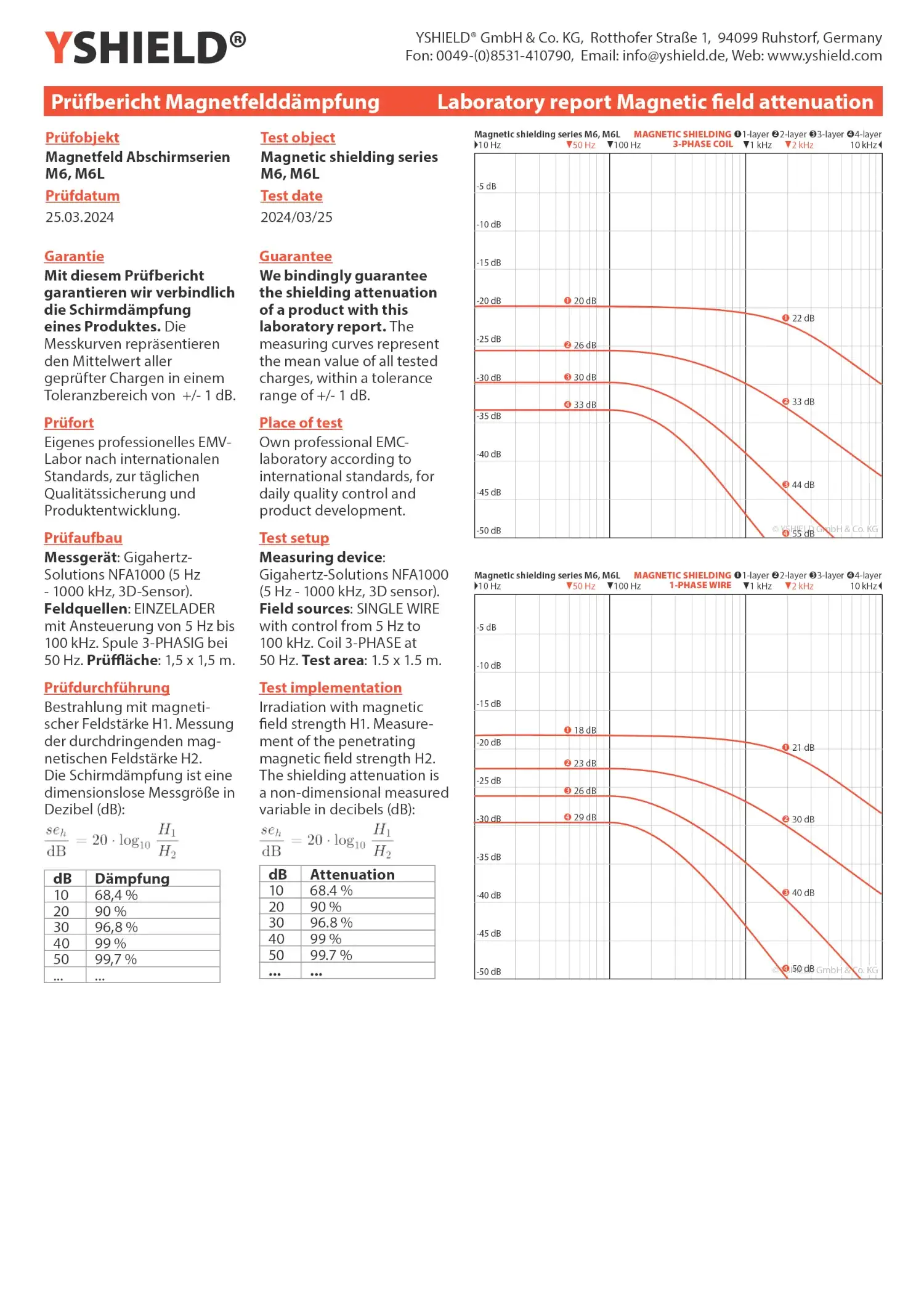

Technical Details of the M6L-64 Magnetic Field Shielding Plate

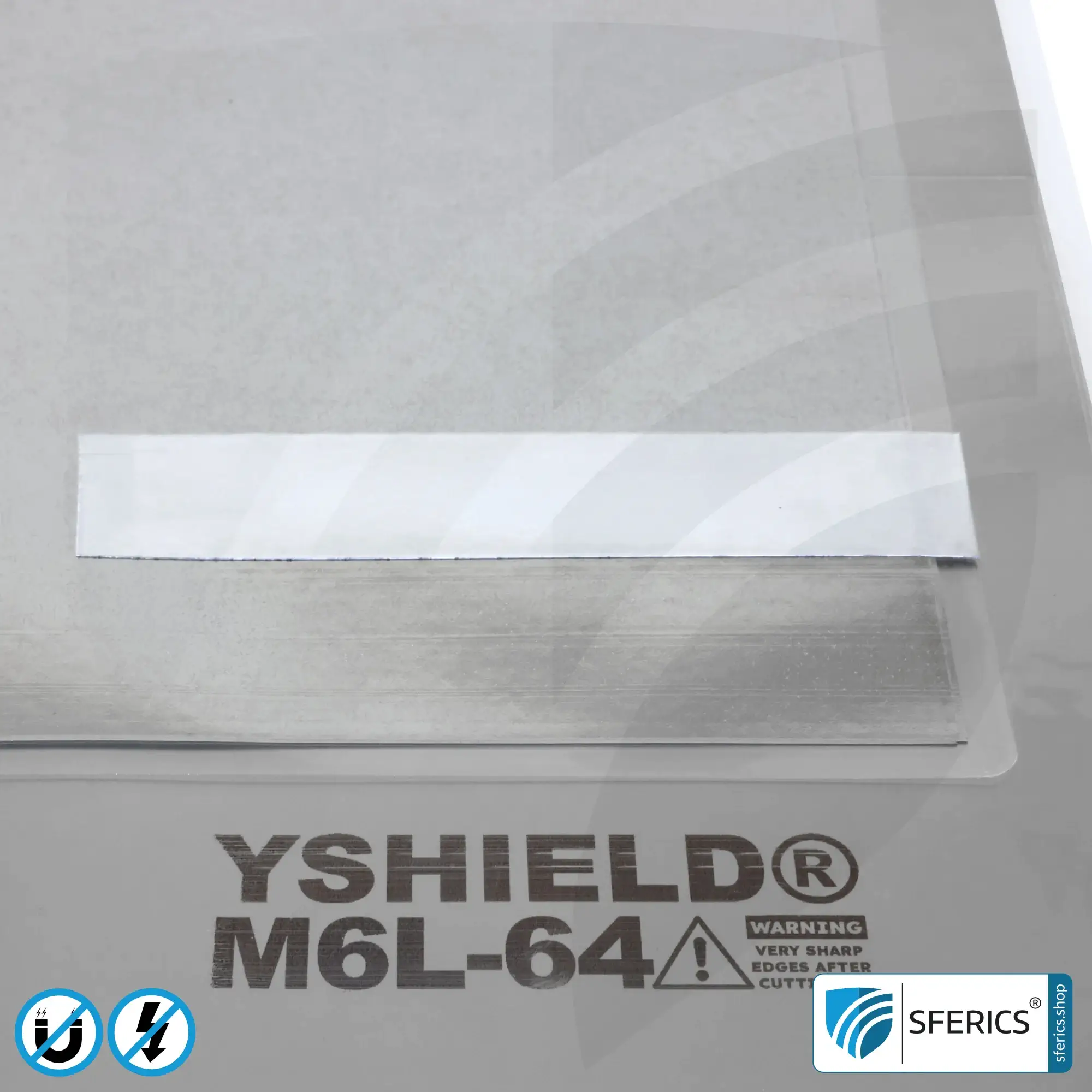

- Dimensions: 59 x 40 cm (shielding surface); 61 x 41 cm (total product)

- Thickness: 0,5 mm (0,7 mm overlapping)

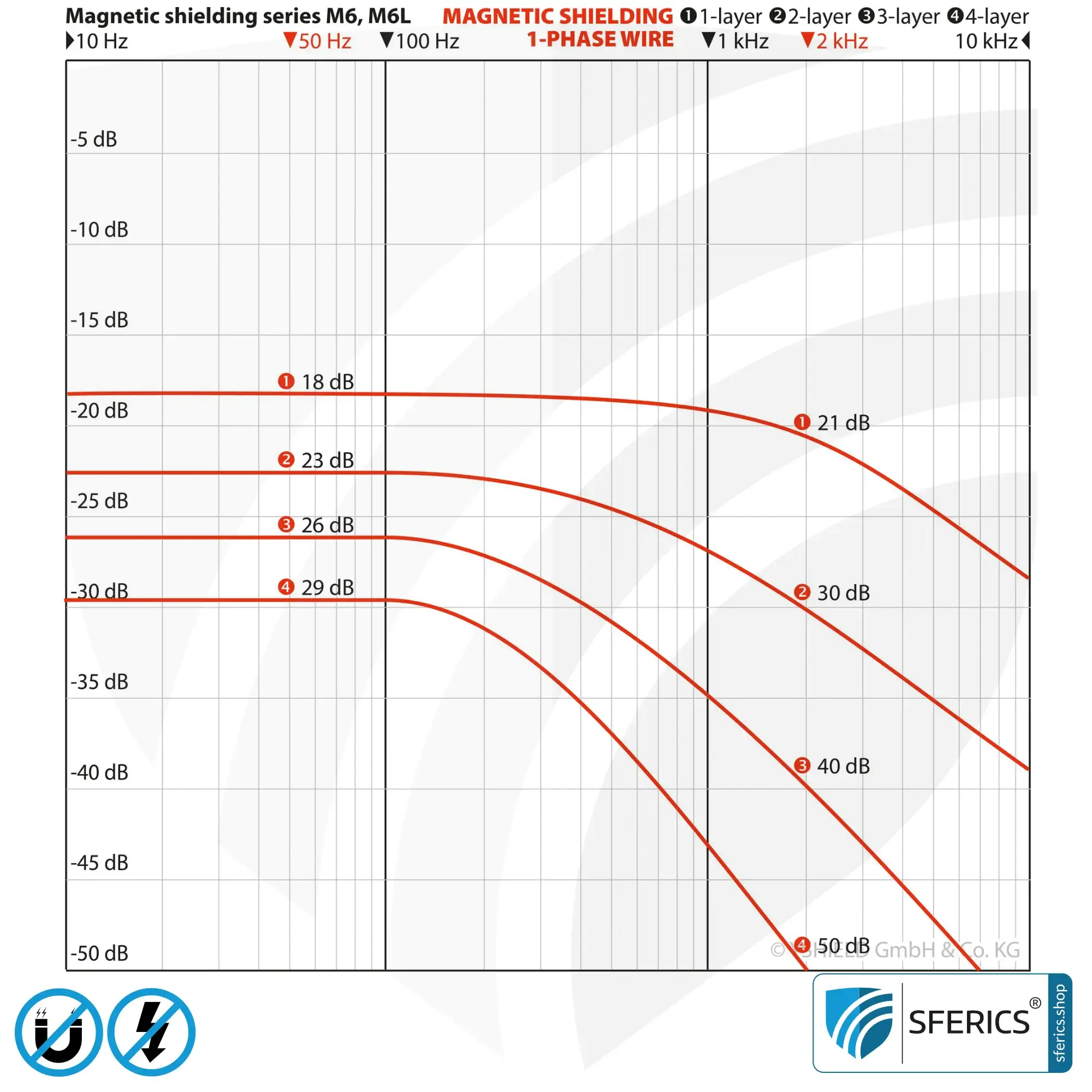

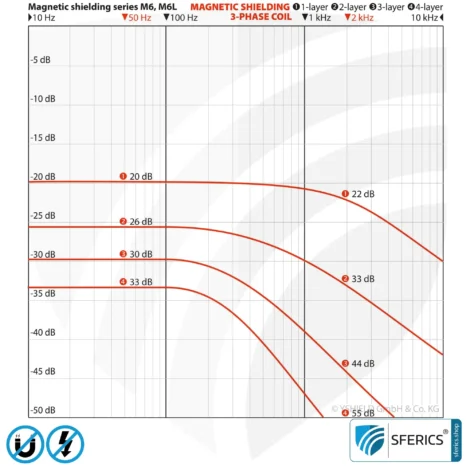

- Magnetic Field Shielding (Three-Phase 50 Hz)

- Single layer: 19,5 dB (89,4 %)

- Double layer: 25,7 dB (94,8 %)

- Triple layer: 30,2 dB (96,9 %)

- Quadruple layer: 32,6 dB (97,7 %)

- Magnetic Field Shielding (Single-Phase 50 Hz):

- Single layer: 17,7 dB (87 %)

- Double layer: 23,2 dB (93,1 %)

- Triple layer: 26,8 dB (95,4 %)

- Quadruple layer: 29,3 dB (96,6 %)

- Magnetic Field Shielding (Static): DC consumers, Earth’s magnetic field, and permanent magnets are shielded in a range from 15 % (single layer) to 58 % (quadruple layer).

- Minimum bending radius: 20 cm

- For innovation reasons, we do not disclose ingredients or magnetic properties. The high-tech material features high initial permeability and high saturation induction from 5 Hz to 50 kHz. Additionally, static magnetic fields at 0 Hz are shielded as well as electromagnetic fields up to 40 GHz.

Processing of the M6L Shielding Plate Series

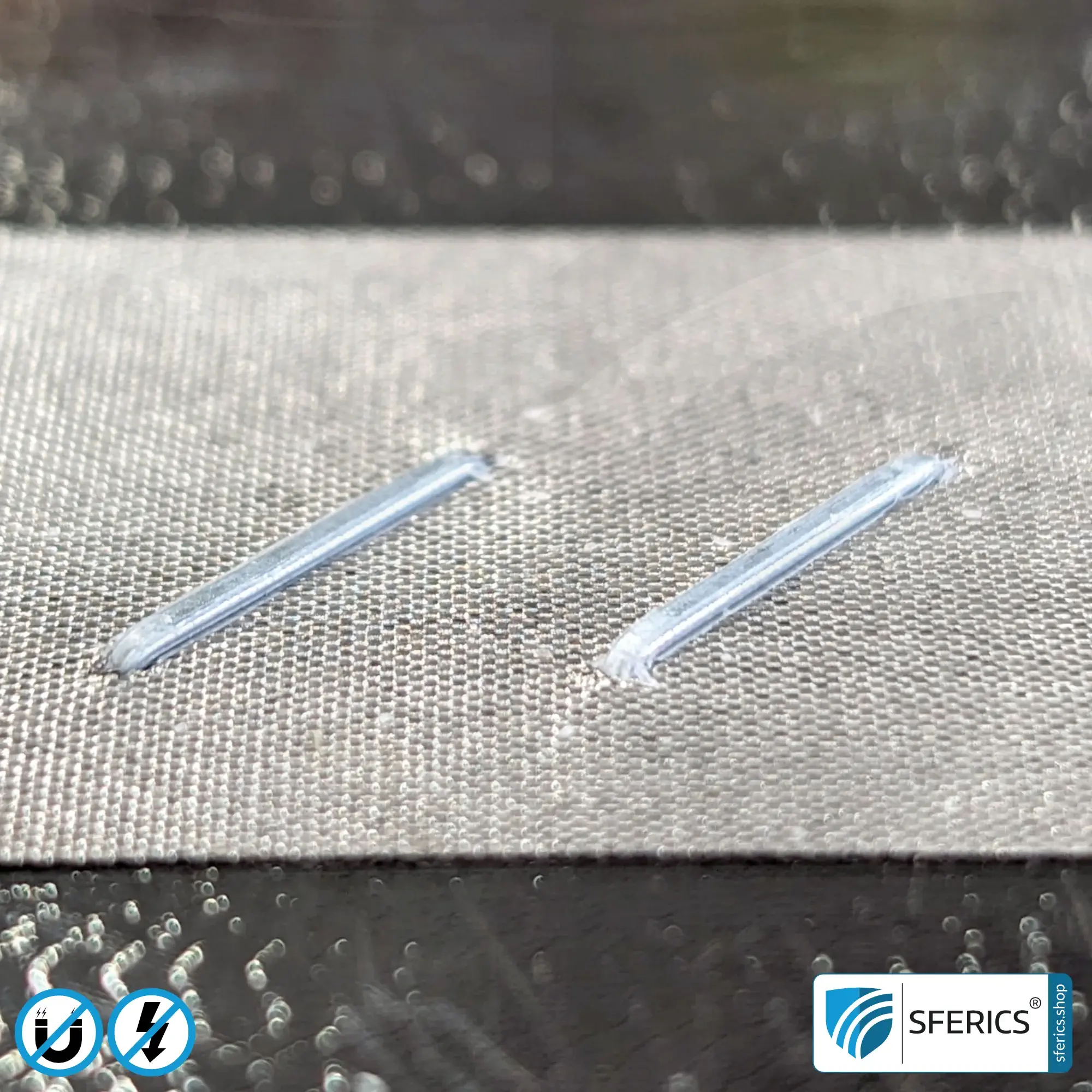

Caution: Risk of Injury from Cuts!

The M6L series can be cut with high-quality scissors! The cut edges are as sharp as a knife and must be immediately protected after cutting, e.g., with fabric adhesive tape! Use cut-resistant gloves during processing!

It’s better to plan the installation of the plates so that cutting is not necessary!

For larger wall surfaces, note that the plates act as a vapor barrier.

Processing with Adhesive:

Choose an adhesive that can bond the PET (polyethylene terephthalate) lamination film. There are high-viscosity mounting adhesives for, e.g., solid substrates, or flexible plastic adhesives for bonding, e.g., under car carpets. Follow the adhesive manufacturer’s instructions.

Processing with Stapler or Nailer:

For suitable substrates, we recommend mounting with an electric stapler or nailer. For a single layer including overlap, a mid-range electric stapler is sufficient; for two or more layers, a professional nailer is required. The shielding surface must overlap by at least 2 cm.

Multi-Layer Installation:

Always install the plates offset, ensuring that the surfaces cover the overlaps underneath.

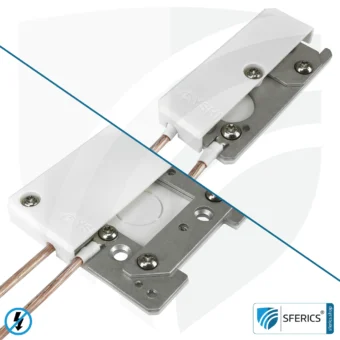

Grounding of the M6L Shielding Plate Series

When shielding magnetic fields, also pay attention to electric fields. To prevent the propagation of electric fields, grounding is necessary.

The M6L series is fully laminated, but there is a solution for making contact: Adhere our grounding tape GSX10 or GSX50 to all surfaces. Staple or nail through the grounding tape with clips or nails. The clips or nails connect the plate and the grounding tape.

Additional components can be found in our shop category “Grounding”.

Test Report & Expert Opinion

Many years ago, the manufacturer invested in its own professional EMC laboratory. This facility is used not only to create test reports but also to test every finished or delivered batch – usually on a daily basis. Additionally, all products are inspected by an independent, renowned expert. Double-checked for double safety. The test report and expert opinion can be found further below under Downloads.

Documentation (.pdf)

| Weight | 0,3 kg |

|---|---|

| Dimensions | 59 × 40 × 0,005 cm |

| Field type | LF (low-frequency electric alternating field), MF (low-frequency magnetic alternating field) |

| Color | silver |

| Brand | |

| Country of origin | Germany |

| Information on product safety | Manufacturer: YSHIELD GmbH & Co. KG, Rotthofer Strasse 1, 94099 Ruhstorf, Germany, Telephone: +498531410790, Email: info@yshield.de |

Magnetic field shielding plate M6L-64 | 59 x 40 cm | six-layered, laminated, and highly resistant

Magnetic field shielding plate M6L-64 | 59 x 40 cm | six-layered, laminated, and highly resistant

Reviews

There are no reviews yet