Shielding Paint SAFEBUILD L40 for Technical Applications | RF Shielding Effectiveness Against Electrosmog up to 90 dB at 40 GHz | No Graphite Effect = Does Not Smudge or Rub Off | TÜV SÜD Certified

Technically our most resilient paint based on carbon fibres (instead of graphite) with a very hard surface that hardly stains. 2019 improved again. The big advantage of the shielding paint is that there is no longer any discoloration when painting over it with or firmly hitting the wall paint above.

Best suited to shielding against radiation caused by mobile phones, DECT, WIFI and mobile internet. Can be grounded to shield against electric alternating fields from the power supply.

RF shielding performance at 1 GHz

- single layer: up to 43 dB

- double layer: up to 49 dB

- triple layer: up to 55 dB

5G frequencies and up to 40 GHz significantly higher, up to 93 dB shielding effectiveness.

Delivery time: approx. 2-5 business days

Please print out “Technical details shielding paints” for the construction site, as no longer available on the container!

€ 39,90

SAFEBUILD L40 shielding paint ia a universal shielding paint for technical applications. New formula eliminates graphite smearing and staining. Up to 90 dB shielding performance at 40 GHz (over 99,9999999% attenuation). TÜV SÜD certified!

After many years of dedicated research and development, YSHIELD has succeeded in creating a groundbreaking new formula that takes the use of graphite in shielding paint to the next level. With the innovative SAFEBUILD L40 shielding paint, the typical smearing and staining caused by graphite is now a thing of the past.

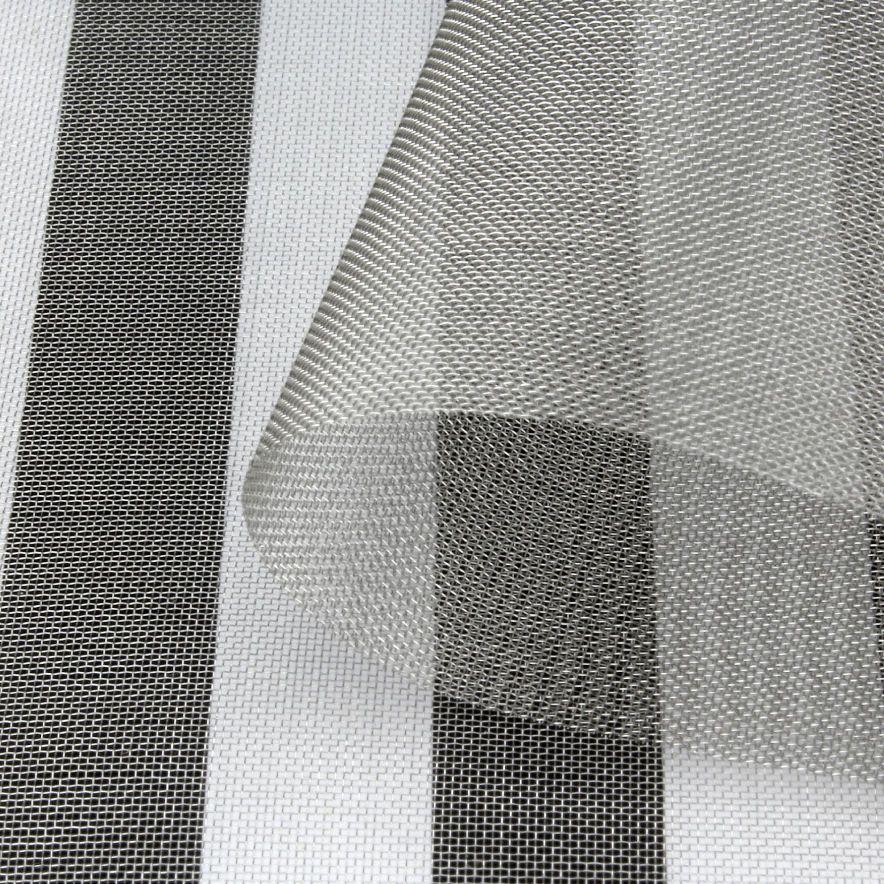

While this shielding paint is a universal solution for electromagnetic shielding—including use in indoor spaces and entire buildings—its ideal application lies in technical environments. The fine pigmentation ensures a highly uniform coating that forms an exceptionally hard and abrasion-resistant film, without the graphite-related residue commonly found in conventional shielding paints.

SAFEBUILD L40 adheres reliably to almost all standard surfaces, offering flexible and user-friendly application across a wide variety of technical use cases. Its shielding performance reaches up to 90 dB at 40 GHz, making it one of the most powerful EMF shielding paints available on the market today.

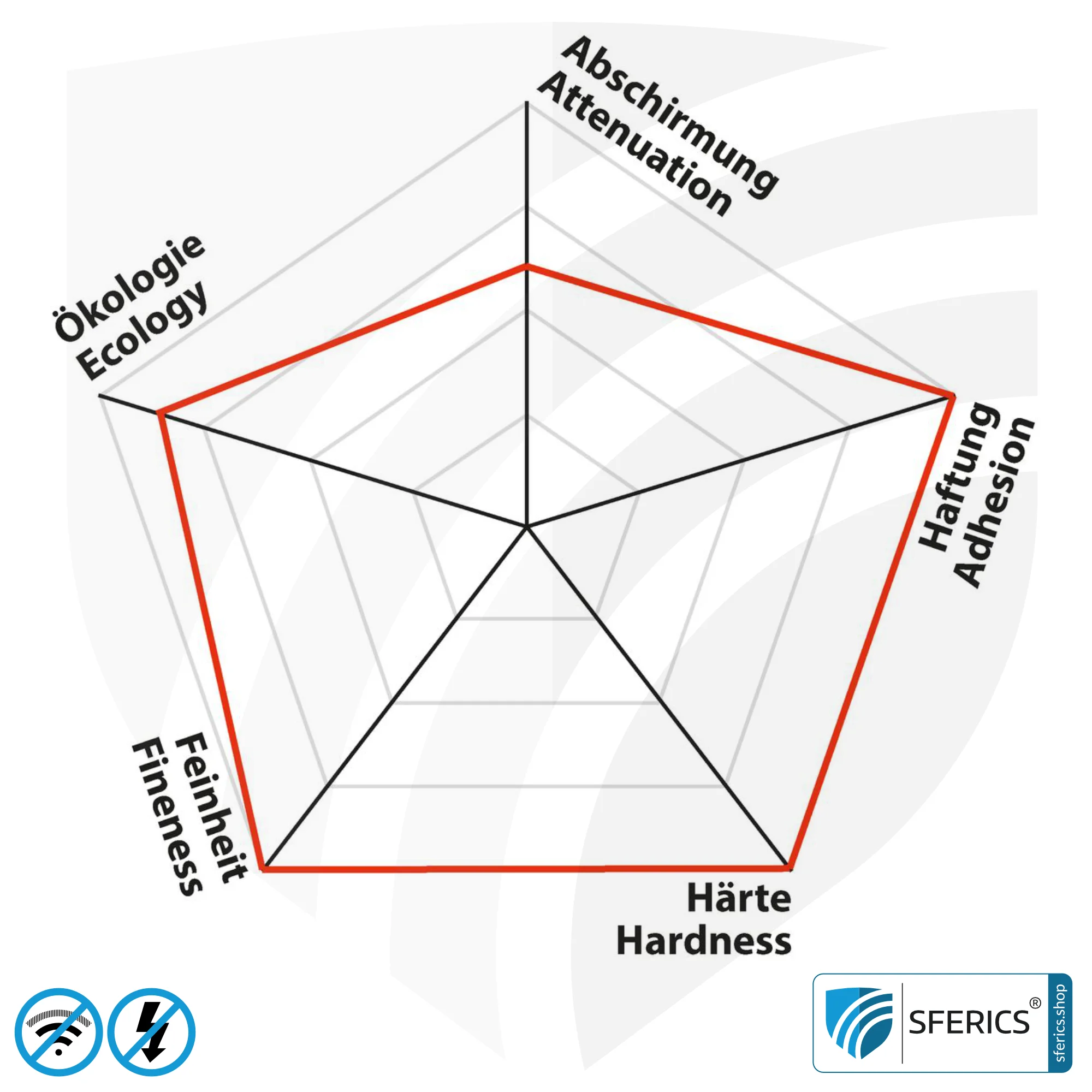

SAFEBUILD L40 Shielding Paint | Key Features

The true breakthrough of this shielding paint lies in the fact that – despite containing graphite – it does not smear, leave graphite residue, or stain surfaces. This makes it a remarkable innovation in the field. Its exceptional adhesion to nearly all types of surfaces is another standout feature. Additional properties and benefits include:

- 40 dB shielding performance at 1 GHz when applied in two layers, which is more than sufficient for most technical applications.

- Very high film hardness and abrasion resistance, ideal for high-wear surfaces. Can even be overcoated with water-based paints.

- Fine pigmentation with d90 under 40 µm; suitable for spray application in technical settings.

- Universal adhesion, even on difficult or low-energy surfaces.

- Improved settling behavior for easy stirring after long storage periods.

- Optimized frost and thaw resistance for reliable performance after freezing during transport.

SAFEBUILD L40 Shielding Paint | Coverage & Yield

In general, the coverage of shielding paint strongly depends on the surface condition. The more absorbent the substrate is, the more shielding paint will be required. For this reason, we recommend performing small-scale tests to observe how quickly the paint is absorbed. To reduce excessive consumption, we strongly suggest using our primer, which minimizes absorption and ensures optimal performance of the SAFEBUILD L40 shielding paint. The stated “average” yield is based on a non-absorbent surface.

Before application, it is essential to stir SAFEBUILD L40 thoroughly. During storage and transport, heavier components may settle at the bottom of the container and must be fully re-integrated. With our specially designed stirring tool, this can be done easily and effectively. Simply attach it to a standard electric drill and mix each container for approximately 5 minutes. No solid residue should remain at the bottom—any unmixed material would reduce shielding performance, as it wouldn’t be properly applied to the surface.

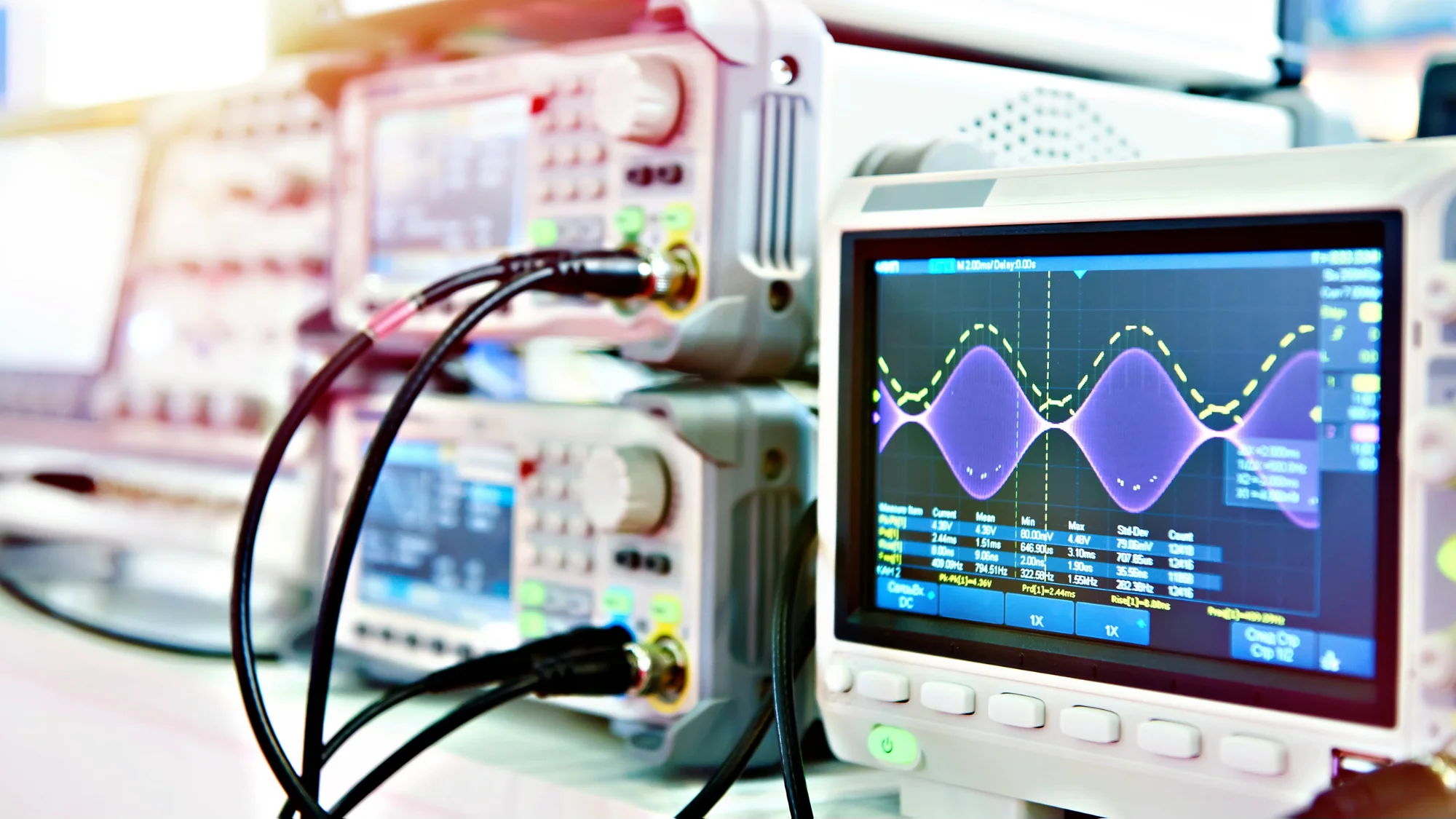

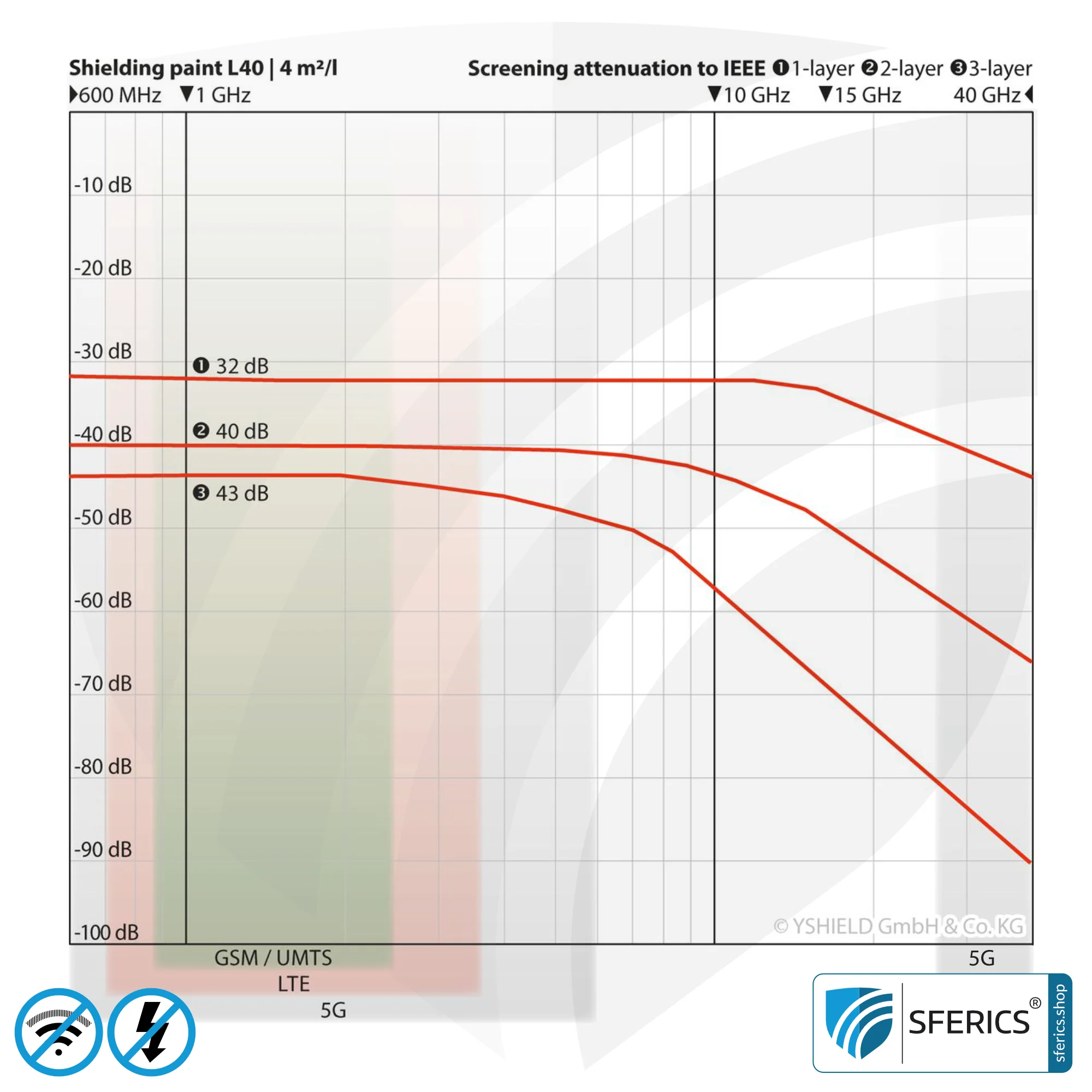

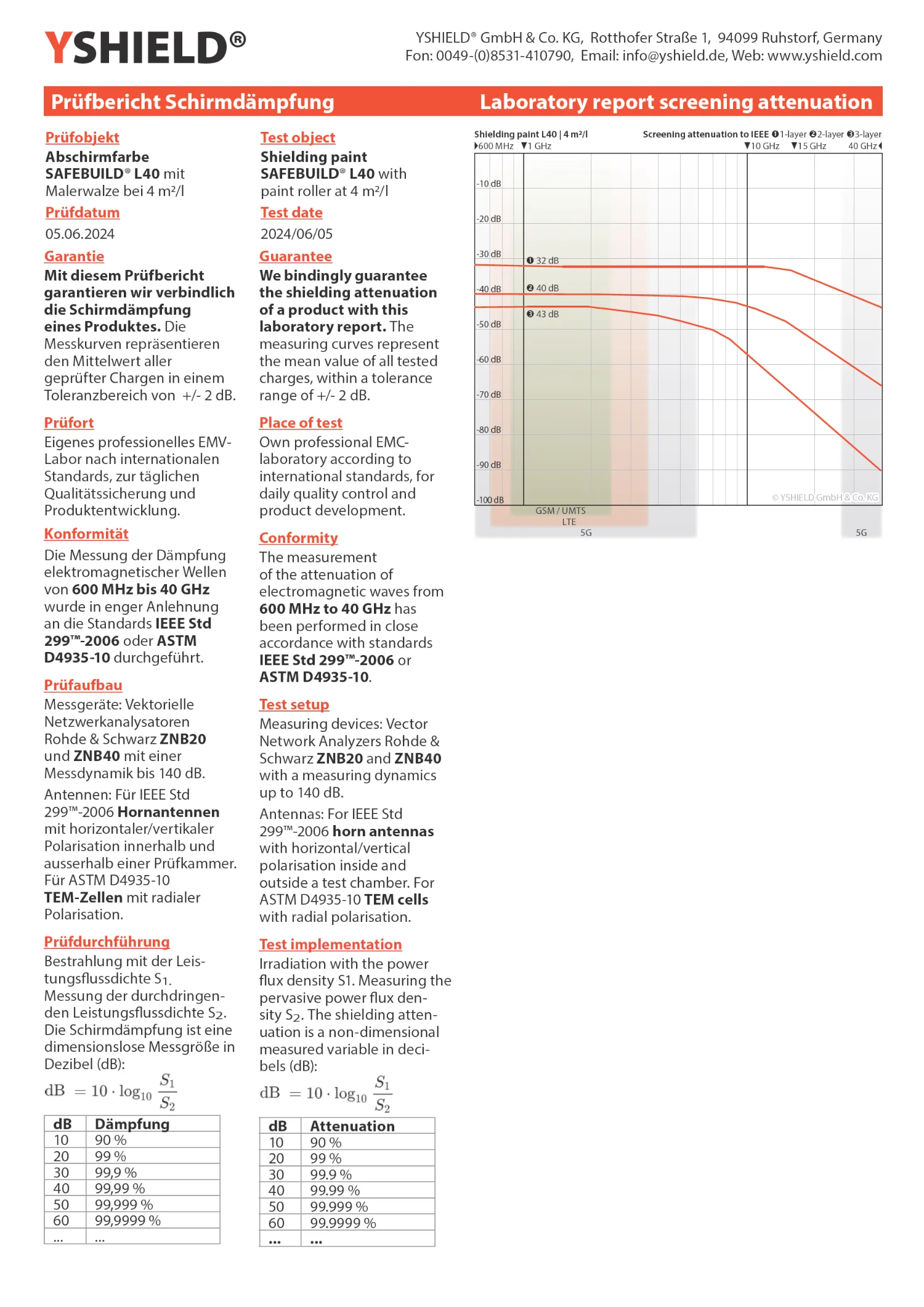

Technical Shielding Effectiveness from the EMF Lab

- With a coverage of 4 m² per liter

At 1 GHz: Single layer: 32 dB | Double layer: 40 dB | Triple layer: 43 dB

At 40 GHz: Single layer: 43 dB | Double layer: 66 dB | Triple layer: 90 dB

Mandatory Grounding of Safebuild L40 Shielding Paint

According to current DIN/VDE regulations, all electrically conductive surfaces must be grounded by a qualified electrician. Grounding can be connected via the home’s electrical grounding system (e.g., the grounding contact in a power outlet) or via grounded metal components such as a radiator pipe. It is also essential that a residual current device (RCD or FI circuit breaker) is installed in the fuse box. Before painting, always disconnect the power supply—an electric shock at 230 volts and 16 amps can be fatal! When painting near electrical outlets, maintain a distance of at least one centimeter from any live flush-mounted boxes.

Low-frequency electric fields can be grounded. In contrast, high-frequency radiation (radiofrequency) behaves differently, as it is based on reflection and therefore cannot be grounded. Shielding from RF radiation works by reflecting the electromagnetic waves, preventing them from entering the room.

SAFEBUILD L40 shielding paint protects against both forms of electrosmog exposure: low-frequency electric fields through grounding, and high-frequency electromagnetic fields through reflection.

SAFEBUILD L40 Shielding Paint | Technical Specifications

- Shielding Effectiveness

When applied in a single layer, Safebuild L40 achieves up to 32 dB shielding at 1 GHz. In two layers, up to 40 dB; and in three layers, up to 43 dB. At higher frequencies (e.g., Wi-Fi, LTE, 5G, and up to 40 GHz), shielding can reach up to 90 dB with three layers. All specified shielding values refer to 1 GHz. Measurements were performed from 600 MHz to 40 GHz, following protocols closely aligned with IEEE Std 299™-2006 and ASTM D4935-10 standards. - Surface Compatibility

Suitable for both interior and exterior use. Excellent adhesion to almost all substrates, including paint coatings, drywall, wallpaper, plaster, concrete, polystyrene, wood, glass, many plastics, and more. - Top Coating

To protect the flexible, black surface from mechanical wear and moisture, we recommend applying a two-layer top coat. Due to the wide variety of paint systems used worldwide, we cannot guarantee compatibility with all products. Additionally, many mineral-based or ecological paints may adhere poorly to the graphite surface of our shielding paint. Always perform a test application on a sample area before full use. - Grounding

Must be grounded! For interior use, we recommend our self-adhesive grounding tape with grounding plate GW (or GB) and grounding plug GP. For exterior use, we recommend the AF3 fiber additive with grounding plate GE. - Ingredients

Water, natural graphite, pure acrylate dispersion, carbon black, additives, and preservatives (BIT, INN, MIT).

| Ready for 5G | Expert report of shielding attenuation up to 40 GHz | TÜV SÜD certification | No nanotechnology |

| Some companies offer “special” 5G-products. This product shields all 5G-frequencies, even without advertising this! Find two gray bars in all shielding diagrams with the 5G frequency spectrums FR1 (600 MHz – 6GHz) and FR2 (24 GHz – 40 GHz). | YSHIELD has already invested in an own professional EMV laboratory years ago. YSHIELD not only use it to create our laboratory screening reports but also to check each batch daily. Additionally, YSHIELD has all products checked by an independent, well-respected expert. Double checked for twice the safety. | YSHIELD has the shielding paints monitored by TÜV SÜD.The complete production process with quality assurance, the emission behaviour and the economical use of preservatives are subject to control. | YSHIELD shielding paints are developed in accordance with strict ecological criteria. YSHIELD uses, for example, the carbon black with the lowest emission possible on the market and untreated natural graphite. They consciously do not use graphene or even newer nanoplatelets, nanomaterials with a completely unclear hazard potential. |

| Weight | N/A |

|---|---|

| Dimensions | N/A |

| Filling quantity | |

| Field type | HF (high-frequency electromagnetic field), LF (low-frequency electric alternating field) |

| Color | black |

| Brand | |

| Country of origin | Germany |

| Information on product safety | Manufacturer: YSHIELD GmbH & Co. KG, Rotthofer Strasse 1, 94099 Ruhstorf, Germany, Telephone: +498531410790, Email: info@yshield.de |

Shielding Paint SAFEBUILD L40 for Technical Applications | RF Shielding Effectiveness Against Electrosmog up to 90 dB at 40 GHz | No Graphite Effect = Does Not Smudge or Rub Off | TÜV SÜD Certified

Shielding Paint SAFEBUILD L40 for Technical Applications | RF Shielding Effectiveness Against Electrosmog up to 90 dB at 40 GHz | No Graphite Effect = Does Not Smudge or Rub Off | TÜV SÜD Certified

Reviews

There are no reviews yet