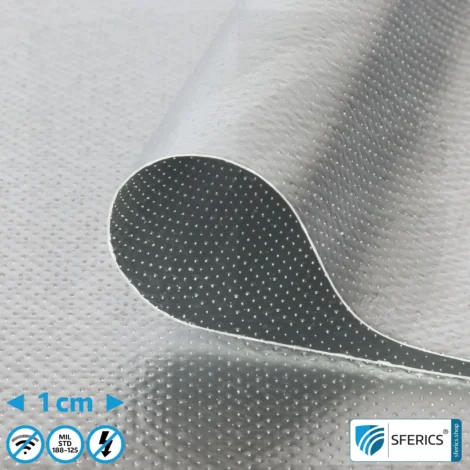

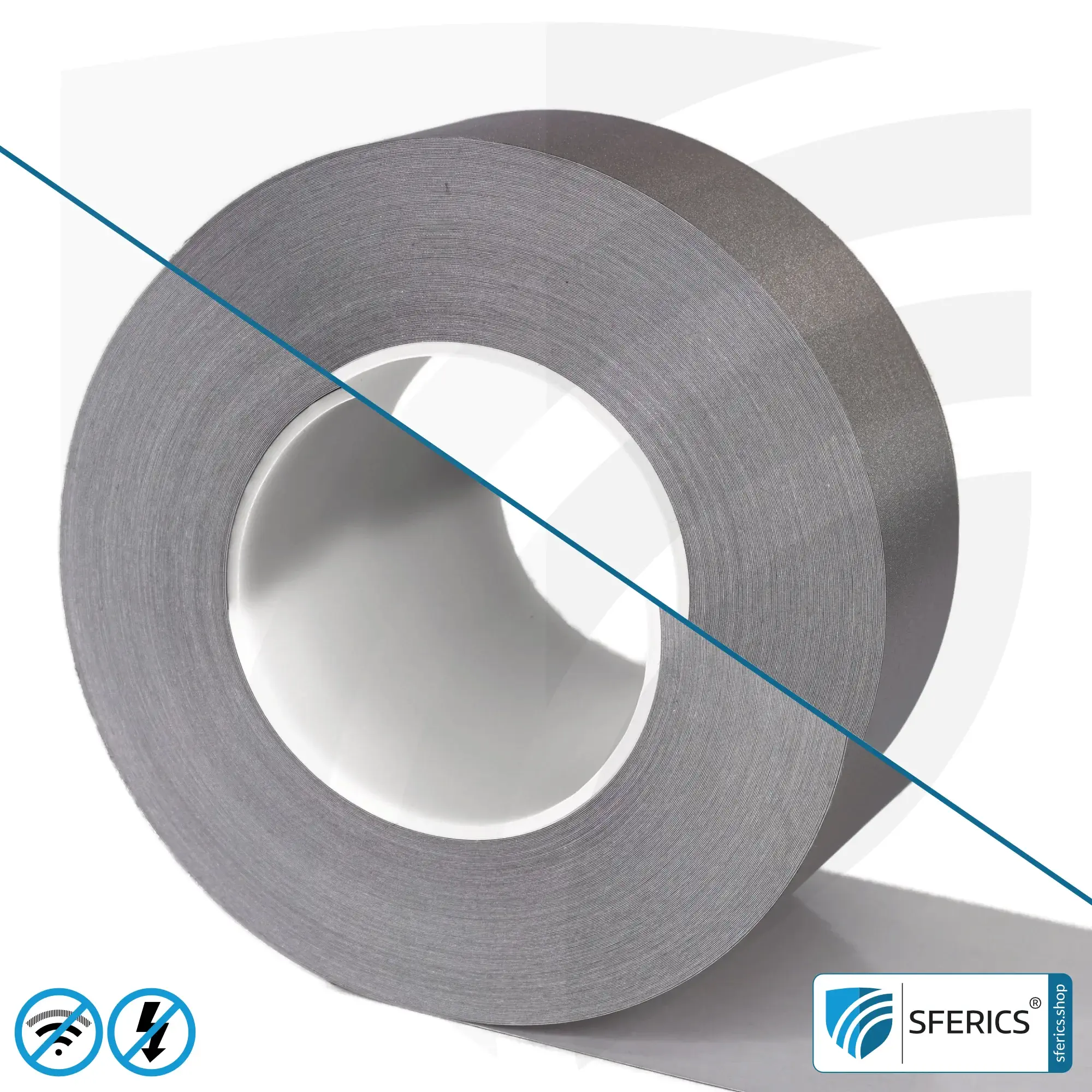

Shielding tape HNX for web edges, self-adhesive | Optimization of shielding attenuation for overlapping seam edges | 50 m length

Self-adhesive shielding tape HNX for optimizing the shielding effectiveness of overlapping web edges.

Delivery time: approx. 1-3 working days

from: € 79,90

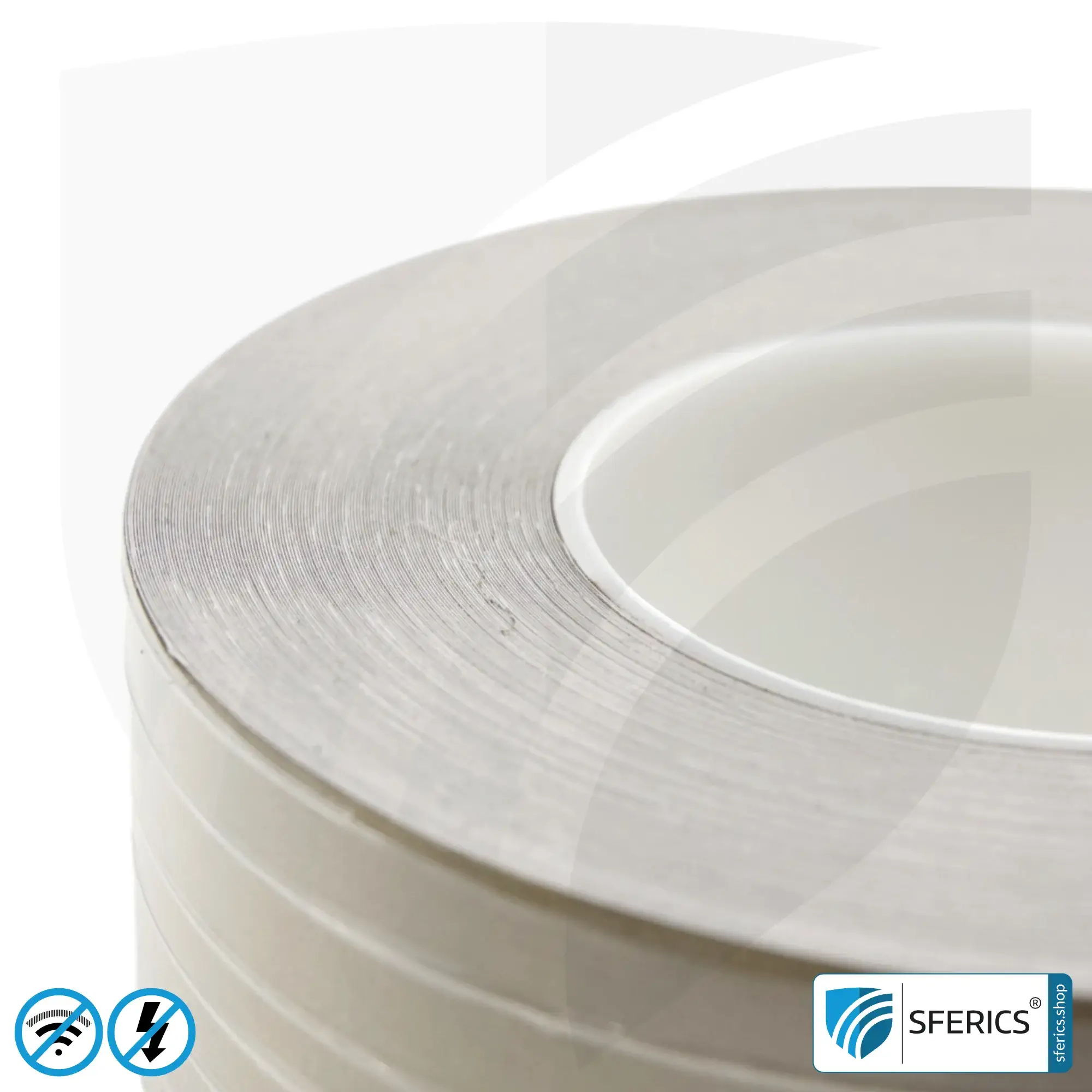

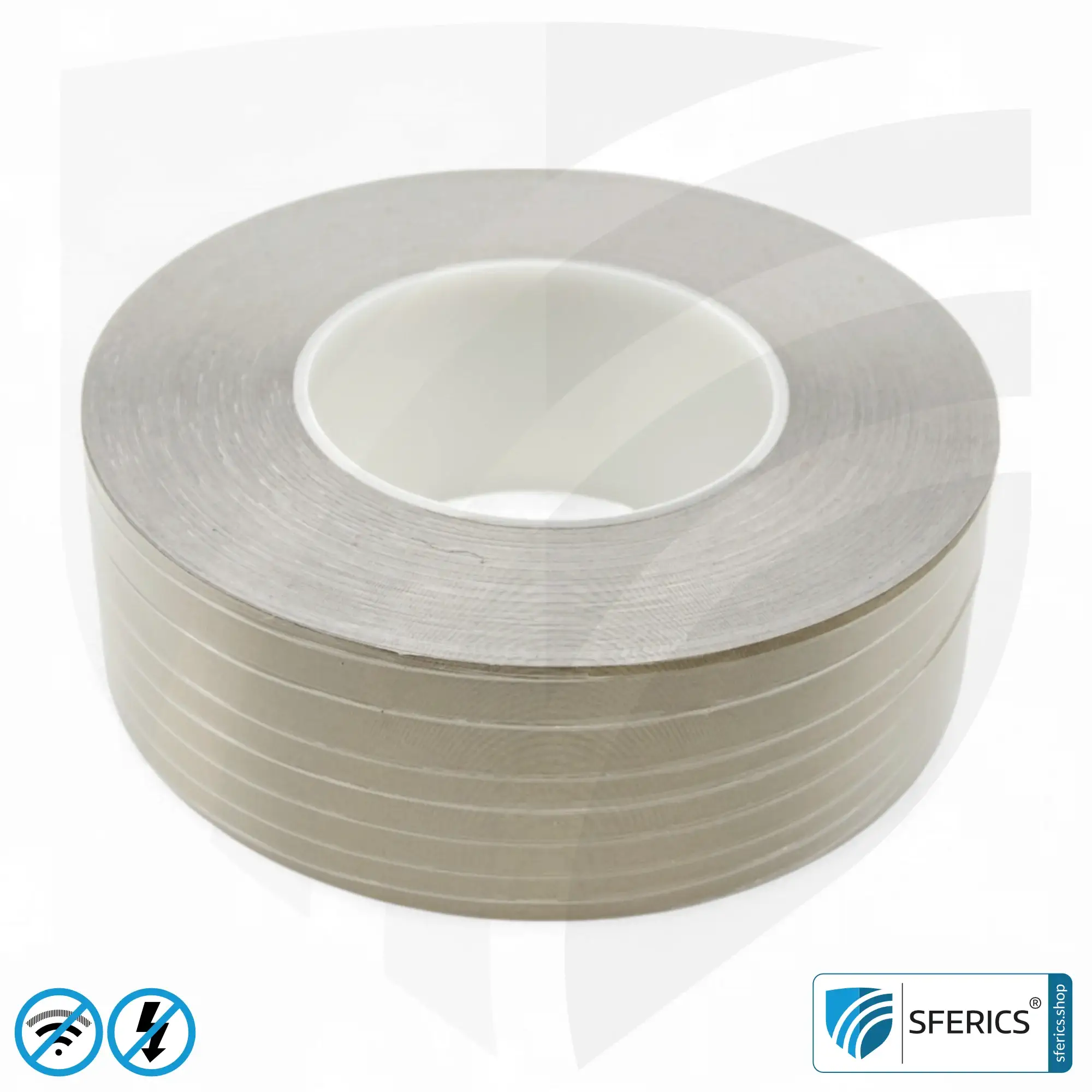

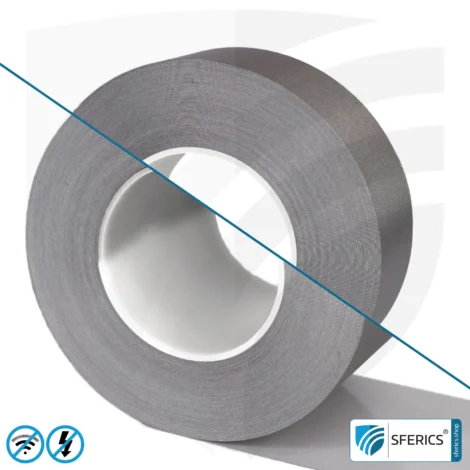

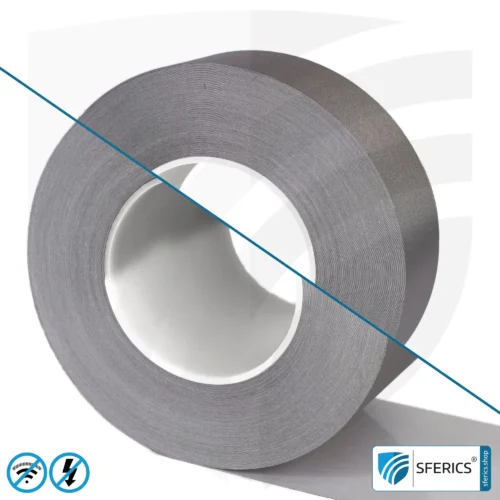

Shielding Tape HNX for web edges, self-adhesive | Optimization of shielding attenuation for overlapping web edges | 50 meters length | 2 widths available: 50 and 100 millimeters

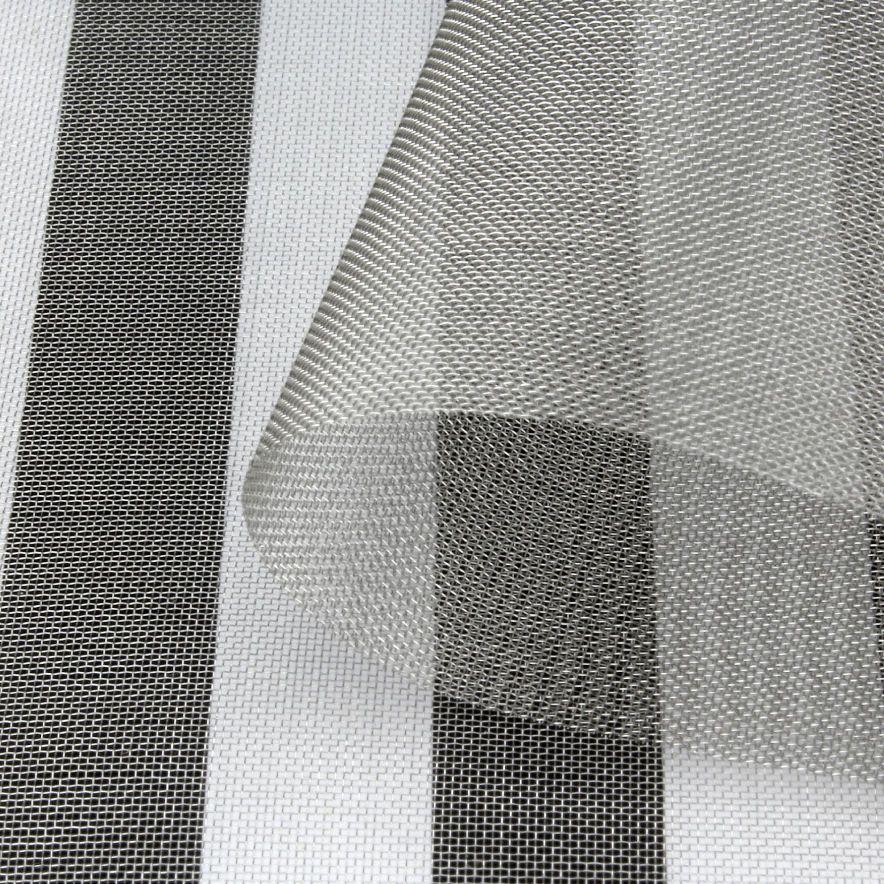

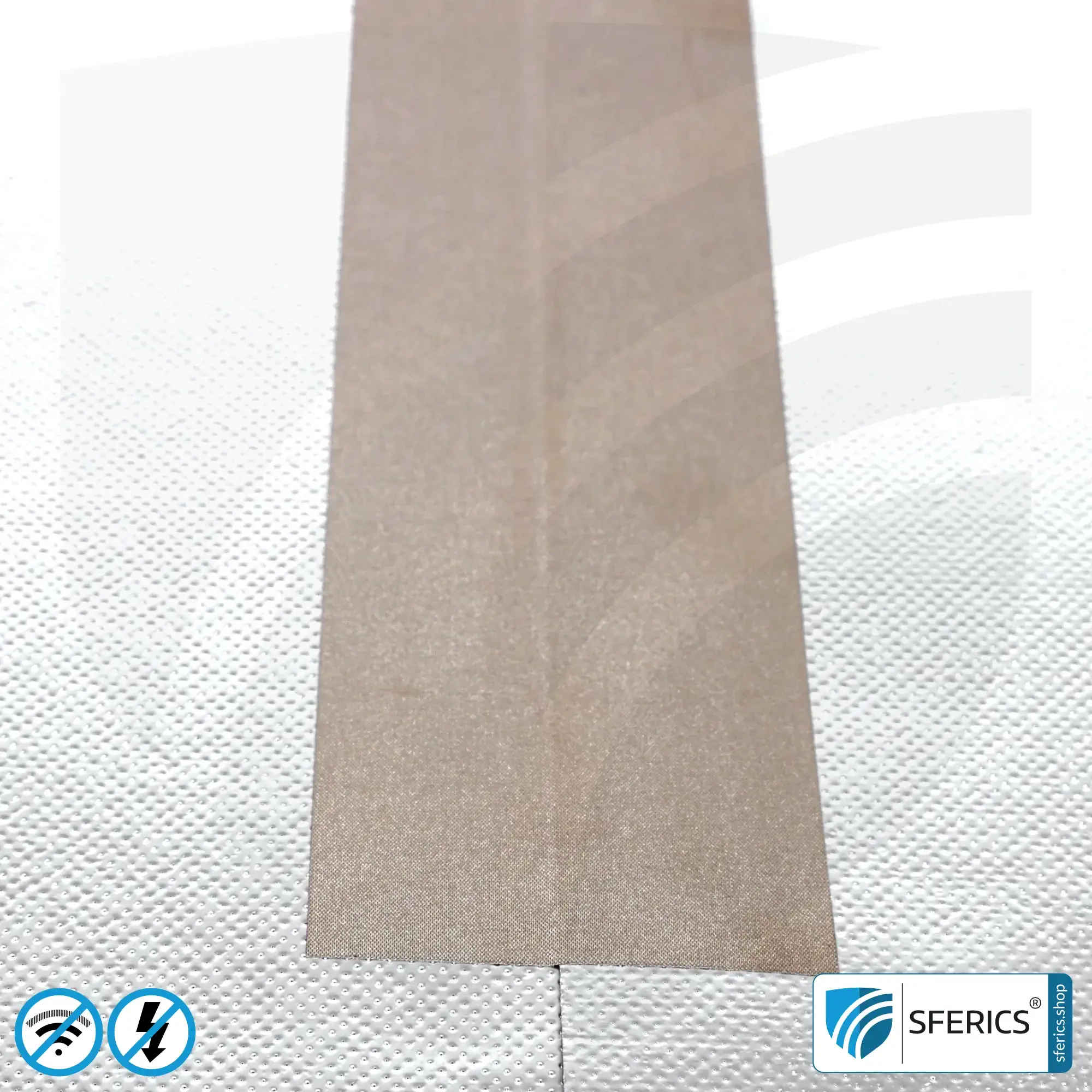

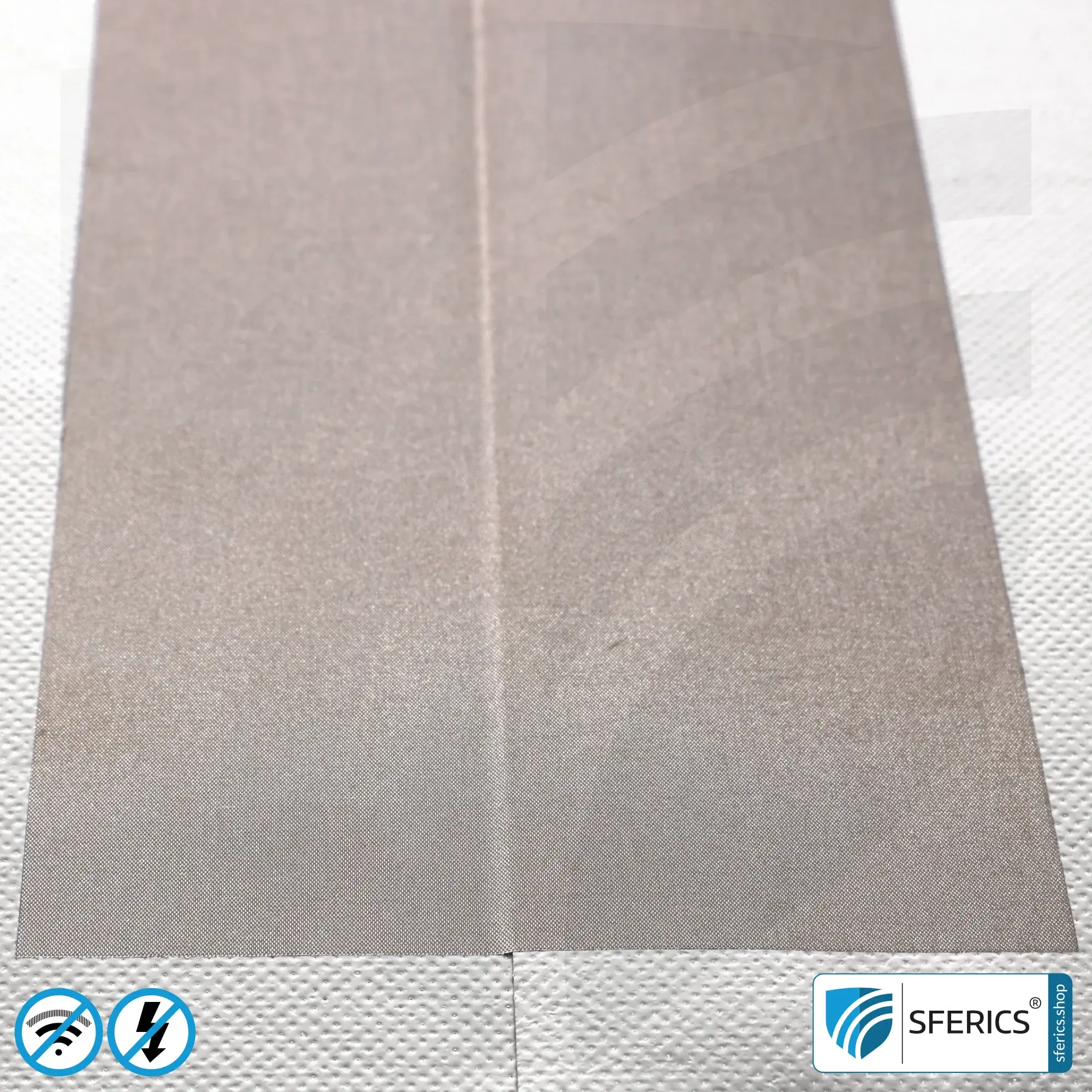

Whenever shielding materials are applied as roll goods in strips, the question inevitably arises as to how the second strip should be laid, i.e., either butt-jointed strip on strip or overlapping by a few centimeters. In either case, the resulting discontinuity in the area of high-performance shielding leads to a reduction in shielding attenuation.

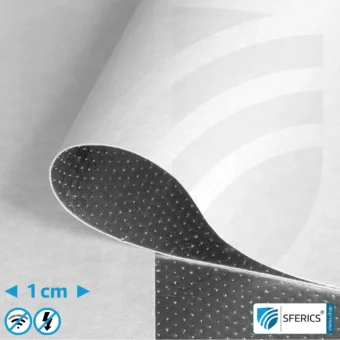

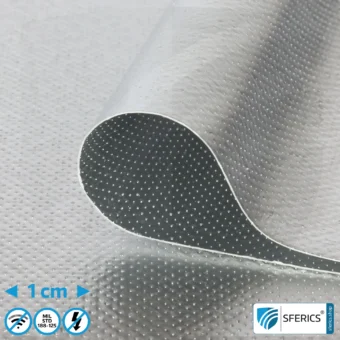

This shielding tape solves the problem once and for all. HNX offers an ideal solution to effectively shield slits, gaps, holes, or overlaps of strips. Compared to smooth metal tapes made of aluminum or copper, this fabric tape with a rough surface achieves a significantly better shielding effect.

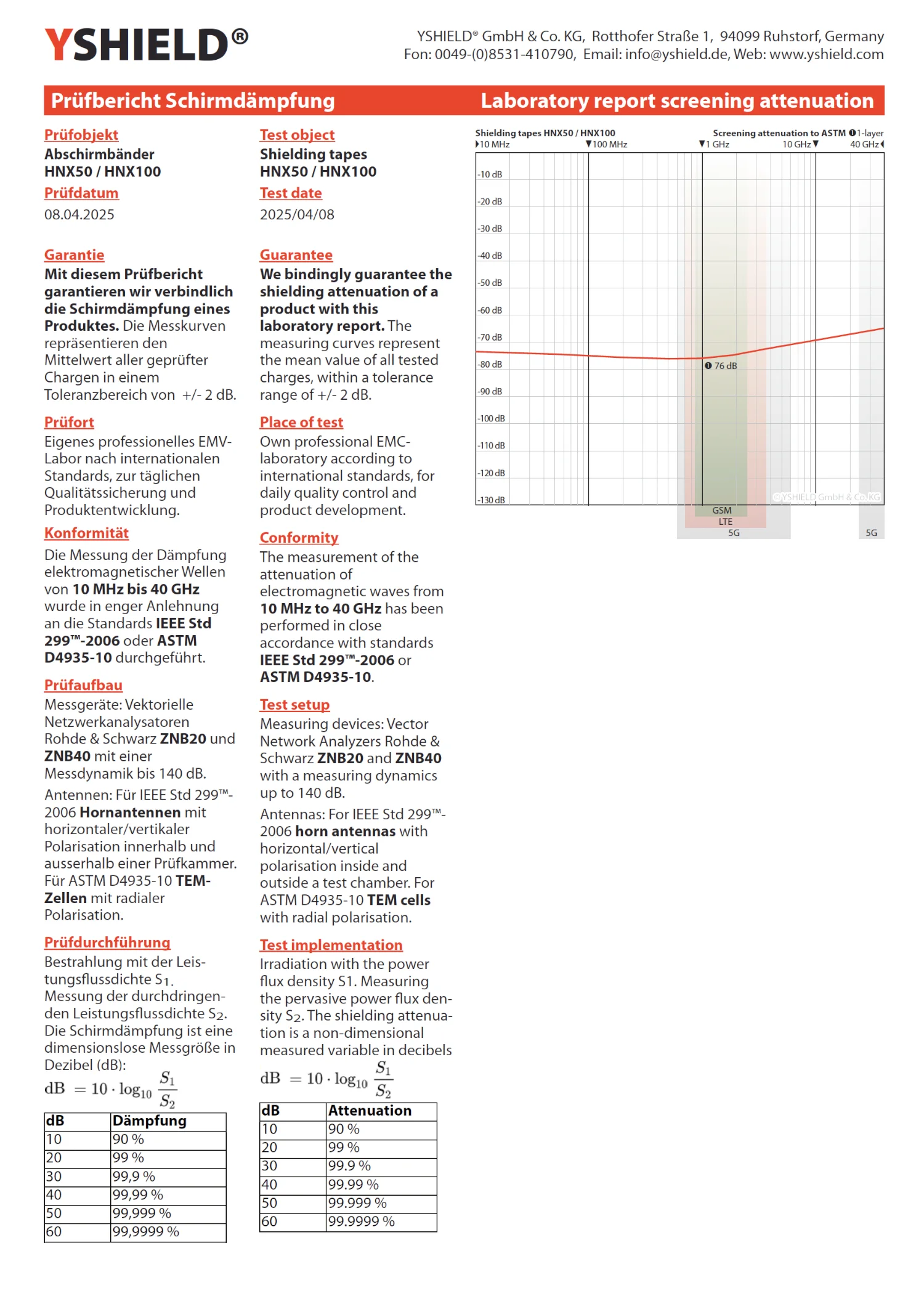

- Shielding attenuation: 76 dB

- Length: 50 m

- Width: 50 mm | 100 mm

- Thickness: 0.11 mm

- For application, we recommend our applicator FVR10

- Materials: polyester, copper, nickel. Conductive acrylic adhesive with high adhesion on the back

HELP: Optimize Shielding Attenuation with Shielding Tapes

We have conducted numerous tests over an extended period and would like to present the results based on a small test series:

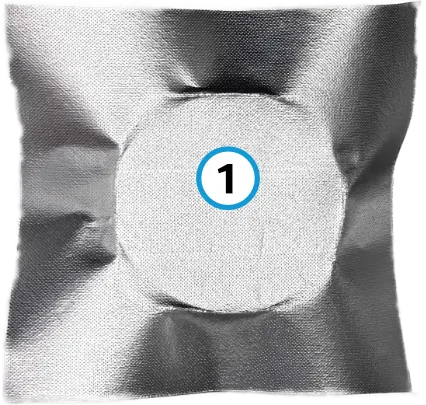

A190 without Overlap

Shielding 112 dB.

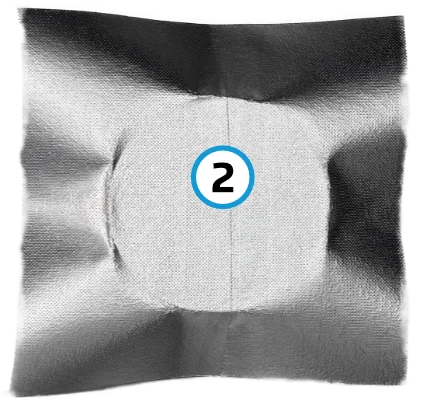

A190 Two Strips Overlapped and Bonded

Shielding 61 dB

A190 with EMC Tape from a Well-Known Manufacturer

Shielding 70 dB

A190 with Standard Aluminum Adhesive Tape

Shielding 68 dB

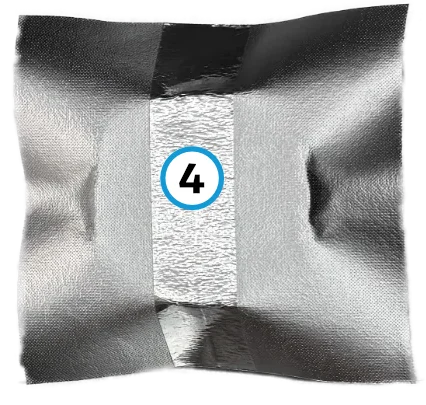

A190 with Our HNX Shielding Tape

Shielding 111 dB

Result | Conclusion

Smooth shielding tape made of copper or aluminum allows radiation to pass through the adhesive layer almost unhindered. Our textile shielding tapes HNX50 and HNX100 significantly reduce radiation through their rough surface when passing through the adhesive layer. This significantly improves shielding attenuation at seam edges and transitions.

Shielding Tapes | Why They Optimize Shielding Performance

For large-area shielding, materials are overlapped at the edges. Depending on the adhesive and material properties, a small gap may form through which radiation can penetrate. For shielding up to 60 dB, no additional measures are necessary. However, to fully utilize the extremely high shielding attenuation of high-end materials such as A300, A190, or K150, a shielding tape for seam edges is required.

In professional EMC laboratories, EMC copper tapes with “electrically conductive” adhesive are often used. The term “electrically conductive” suggests that the adhesive layer blocks radiation. In reality, the adhesive is only “electrically contactable.” It contains a few tiny carbon or metal particles that, with sufficient pressure, electrically connect the upper and lower layers but allow radiation to pass through largely unhindered.

Reviews

There are no reviews yet