Shielding paint NSF34 | LF screening attenuation against electrosmog up to 80 dB | protection against low-frequency electrical fields (domestic electricity) | TÜV SÜD certified

NSF34 is an effective shielding paint for dealing with low-frequency electric alternating fields. Based on pure acrylate, this paint’s shielding attenuation goes up to an impressive 80 dB.

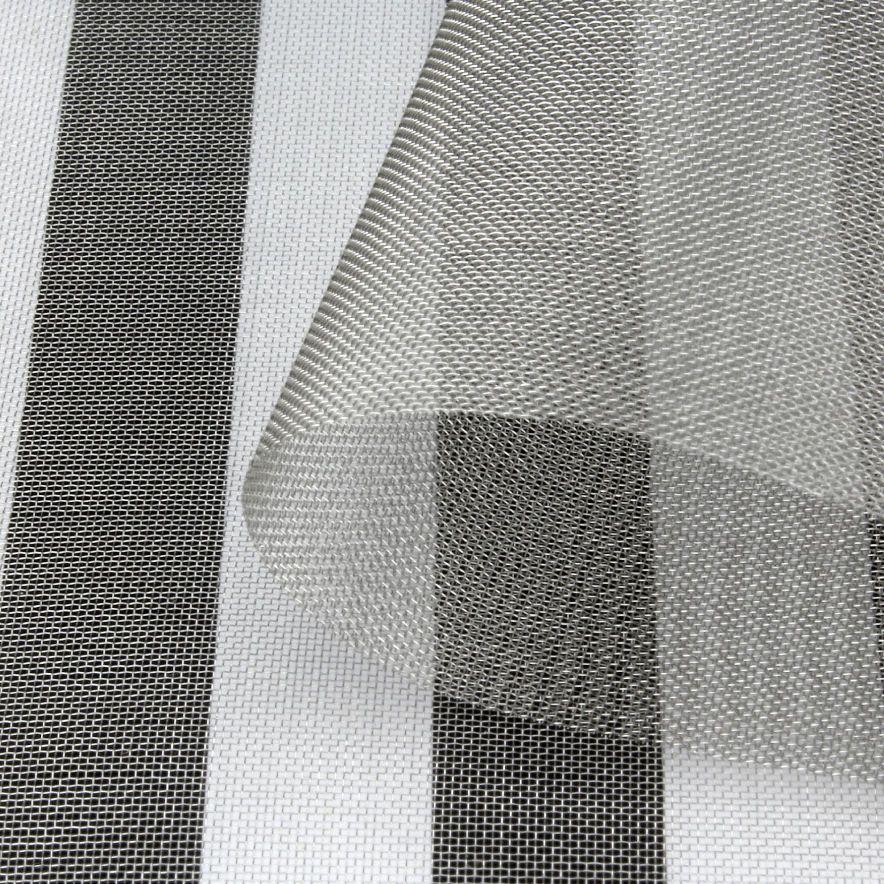

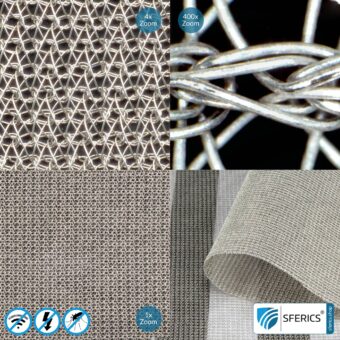

Protection against immissions by radio radiation (mobile phone, WIFI, mobile Internet, DECT, …) is not possible with this shielding paint NSF34. A direct alternative product, also limited on LF shielding, is our shielding fleece NCV95.

No longer available | To the alternative HSF54

NSF34 is a shielding paint developed for the effective shielding of low-frequency alternating electric fields. LF shielding attenuation up to 80 dB. Without protective effect against electrosmog caused by radio radiation (EMF).

Normally, our focus is on total protection from electrosmog. However, in some cases, a special shielding paint, such as the NSF34 by YSHIELD, can make sense. For example, in an office if the radio reception cannot be impaired if, for example, a structured cabling is missing and all of the computers, laptops, and peripheral devices are connected to WLAN. Or, if there is no landline telephone and communication is only done by mobile phone.

Or, in private rooms such as the living room or home office if your mobile phone has to have reception, but protection from the electric alternating fields goes through the power cabling in the wall. This paint can also be used later under photovoltaic systems if the low-frequency electric field produced by the panels shouldn’t enter the living room.

This special LF shielding is seldom used compared to the all-round electrosmog shielding paint. This NSF34 shielding paint has no use in bedrooms focused on recovery and we advise against its usage.

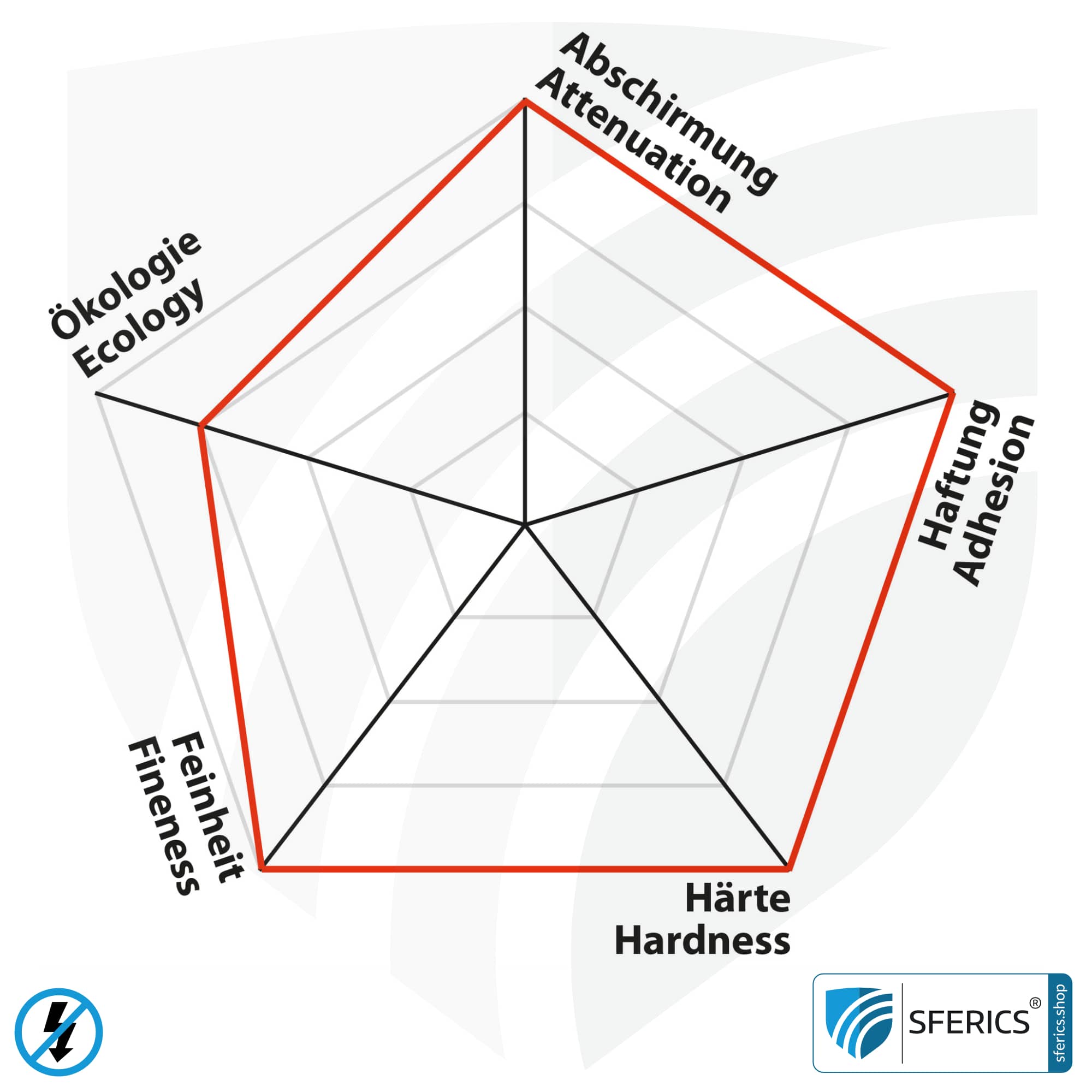

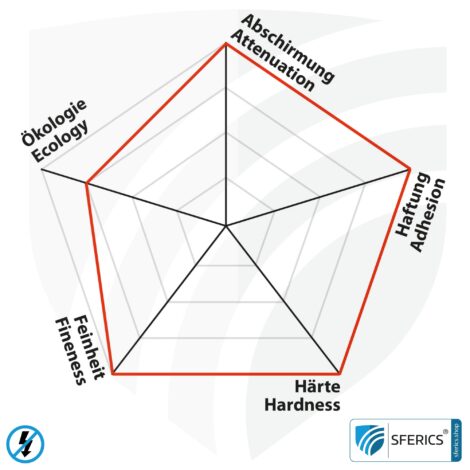

Shielding Paint NSF34 | Characteristics

The NSF34 shielding paint was developed with a high-quality pure acrylic binder and offers a high attenuation of up to 80 dB against low-frequency electric fields. By using NSF34, it is possible to fully shield yourself from LF loads from electric fields from the power supply. NSF34 is frost-resistant and ideal for year-round shipping. It is also breathable, solvent-free, low-odor and low-emission.

One coat is NSF34 is normally enough. The NSF34 shielding paint must be grounded!

- Screening attenuation: One coat provides 80 dB attenuation against low-frequency electric fields (LF). The shielding attenuation is often measured in the EMC laboratory. The measurement setups used follow these standards: ASTM D4935-10, IEEE Std 299-2006, IEEEE Std 1128-1998, ASTM A698/A698M-07.

- Substrate: Indoors and outdoors. Excellent on adhesion on almost all substrates such as old coats of paint, plasterboards, wallpapers, plaster, concrete, styrofoam, wood, etc.

- Final coating: Preferably covered with plastic-bonded dispersion paints, silicate emulsion paints, façade paints or silicon resin paints. We do not recommend pure mineral paints (clay, chalk, pure silicate). You can find concrete recommendations on the technical data sheet. Due to its high tensile strength (at least 0.08 N/mm² according to ETAG 004 for WDVS), it can be applied directly under pure organic plaster, but not on mineral plaster!

- Grounding: Must be grounded! We recommend the self-adhesive grounding tape for indoor use.

Shielding Paint NSF34 | Yield

Generally speaking, the yield of a shielding paint is necessary depending on the surface. The more the surface “sucks”, ie. is coloured, the more shielding paint is required. We recommend conducting small tests to see how quickly the paint “enters”. We highly recommend using our primer because that will prevent an excessively-high usage of NSF34 shielding paint. The “average” yield is based on a “non-sucking” surface.

- 1 liter of NSF34 is enough to cover up to 7.5 m² of an indoor surface

- 1 liter of NSF34 is enough to cover up to 5 m² of an outdoor surface

You need to mix the NSF34 shielding paint extensively before applying it. The heavier ingredients will have sunk from storage and transport, and this must be corrected. With the stirrer developed by us it is possible to effortlessly and effectively re-mix and re-apply the NSF34 shielding paint. Simply insert it into a standard electric drill and mix for around 5 minutes per container. There should be no more solid remains of the solid ingredients at the bottom of the container – these would make the shielding less effective because they wouldn’t be put on the wall, but they’d remain in the paint bucket.

Mandatory grounding of the NSF34 shielding paint

All electrically conductive surfaces must be grounded by a qualified electrician in accordance to the DIN/VDE regulations. This can be done over the electrical system’s grounding support (ground contact in the socket) or on the grounded heating pipe of the wall heaters (radiator). A protective circuit also needs to be installed in the fuse box. It must be noted that the circuit must be turned off before painting – a 230-volt, 16-amp shock can be deadly! The electrified flush-mounted box must be a centimeter away when painting the wall.

Electric alternating fields can be grounded.

The NSF34 shielding paint only shields against low-frequency electric fields through grounding.

Shielding Paint NSF34 | Technical Details

- Screening attenuation

One coat of NSF34 attenuates by up to 80 dB. Only protection against low-frequency electric fields (LF) is provided. The shielding attenuation is often measured in the EMC laboratory. The measurement setups used follow these standards: ASTM D4935-10, IEEE Std 299-2006, IEEEE Std 1128-1998, ASTM A698/A698M-07. - Yield

Indoors (7.5 m²/L), outdoors (5 m²/L). - Substrate

Indoors and outdoors. Excellent adhesion on almost all substrates such as old coats of paint, plasterboards, wallpapers, plaster, concrete, styrofoam, wood, etc. - Application

Indoor walls, outdoor walls, ceilings, floors - Final coating

Preferably covered with plastic-bonded dispersion paints, silicate emulsion paints, façade paints or silicon resin paints. We do not recommend pure mineral paints (clay, chalk, pure silicate). You can find concrete recommendations on the technical data sheet. Due to its high tensile strength (at least 0.08 N/mm² according to ETAG 004 for WDVS), it can be applied directly under pure organic plaster, but not on mineral plaster! - Earth

Must be grounded! We recommend the self-adhesive grounding tape for indoor use. - Ingredients

Water, pure acrylic dispersion, carbon black, natural graphite, additives, preservatives (BIT, INN, MIT)

| As coating in technical applications | TÜV SÜD certification | No nanotechnology |

| With the fine pigmentation of 5 µm, high film hardness, good substrate wetting, high tensile adhesion values and Newtonian rheology, customers have discovered more and more technical applications over the years: technical shielding of parts, devices, machines or plants. Production of absorber materials or pressure sensors. Screen printing on heating foils or plasterboard. | YSHIELD has the shielding paints monitored by TÜV SÜD. The complete production process with quality assurance, the emission behaviour and the economical use of preservatives are subject to control. The certificate can be found above under “Documentation & Downloads”. |

YSHIELD shielding paints are developed according to strict ecological criteria. For example, the lowest emission carbon black on the market and untreated natural graphite are used. YSHIELD deliberately avoids the use of graphene, a nanomaterial with a still completely unclear potential for danger. |

| Filling quantity | |

|---|---|

| Field type | LF (low-frequency electric alternating field) |

| Color | black |

| Brand | |

| Country of origin | Germany |

| PROnatur24 Feed | nein |

1 review for Shielding paint NSF34 | LF screening attenuation against electrosmog up to 80 dB | protection against low-frequency electrical fields (domestic electricity) | TÜV SÜD certified

| 5 star | 100% | |

| 4 star | 0% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

Shielding paint NSF34 | LF screening attenuation against electrosmog up to 80 dB | protection against low-frequency electrical fields (domestic electricity) | TÜV SÜD certified

Shielding paint NSF34 | LF screening attenuation against electrosmog up to 80 dB | protection against low-frequency electrical fields (domestic electricity) | TÜV SÜD certified

Top product and helpful additional information from the company