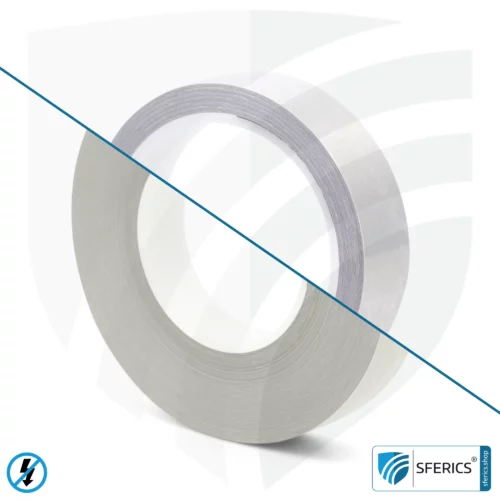

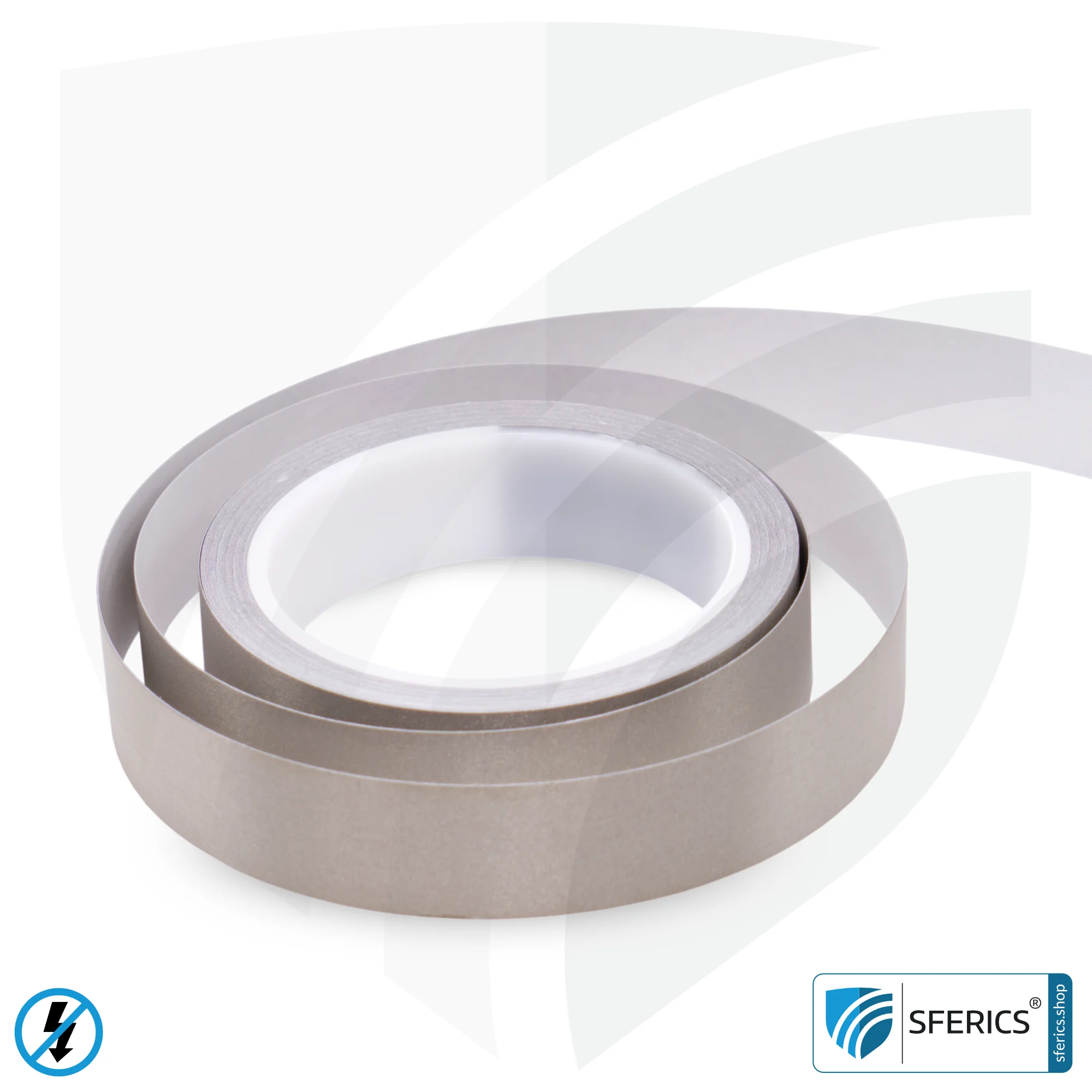

Grounding strap GSX, self-adhesive | grounding of shielding paint, shielding netting, shielding fleece, etc.

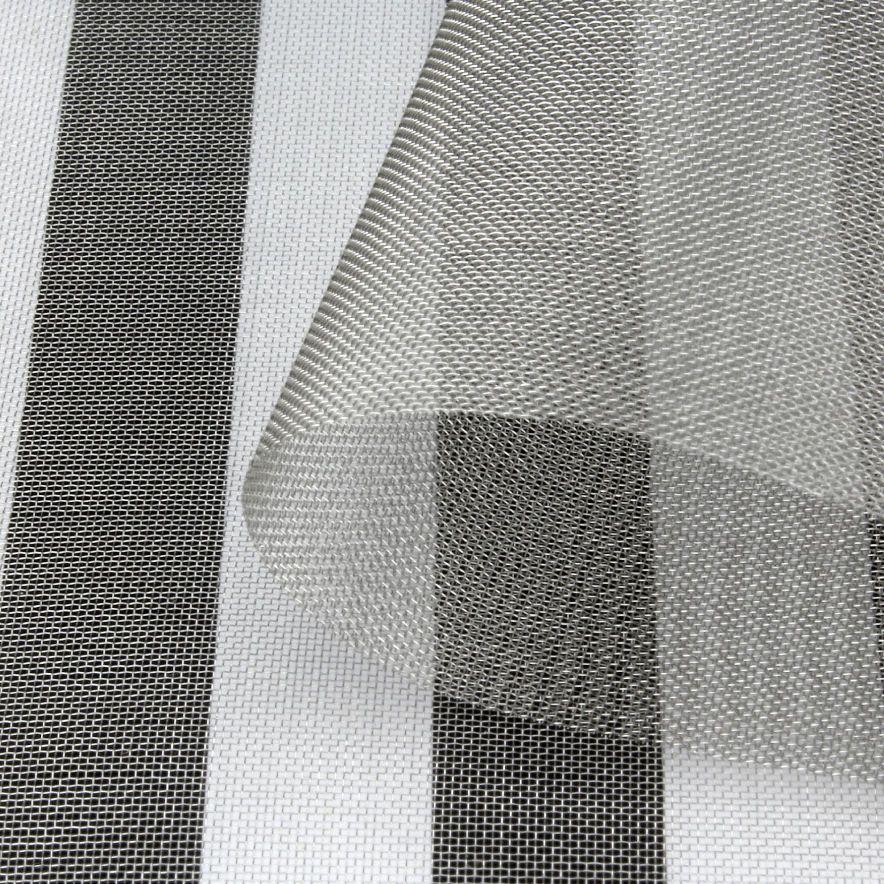

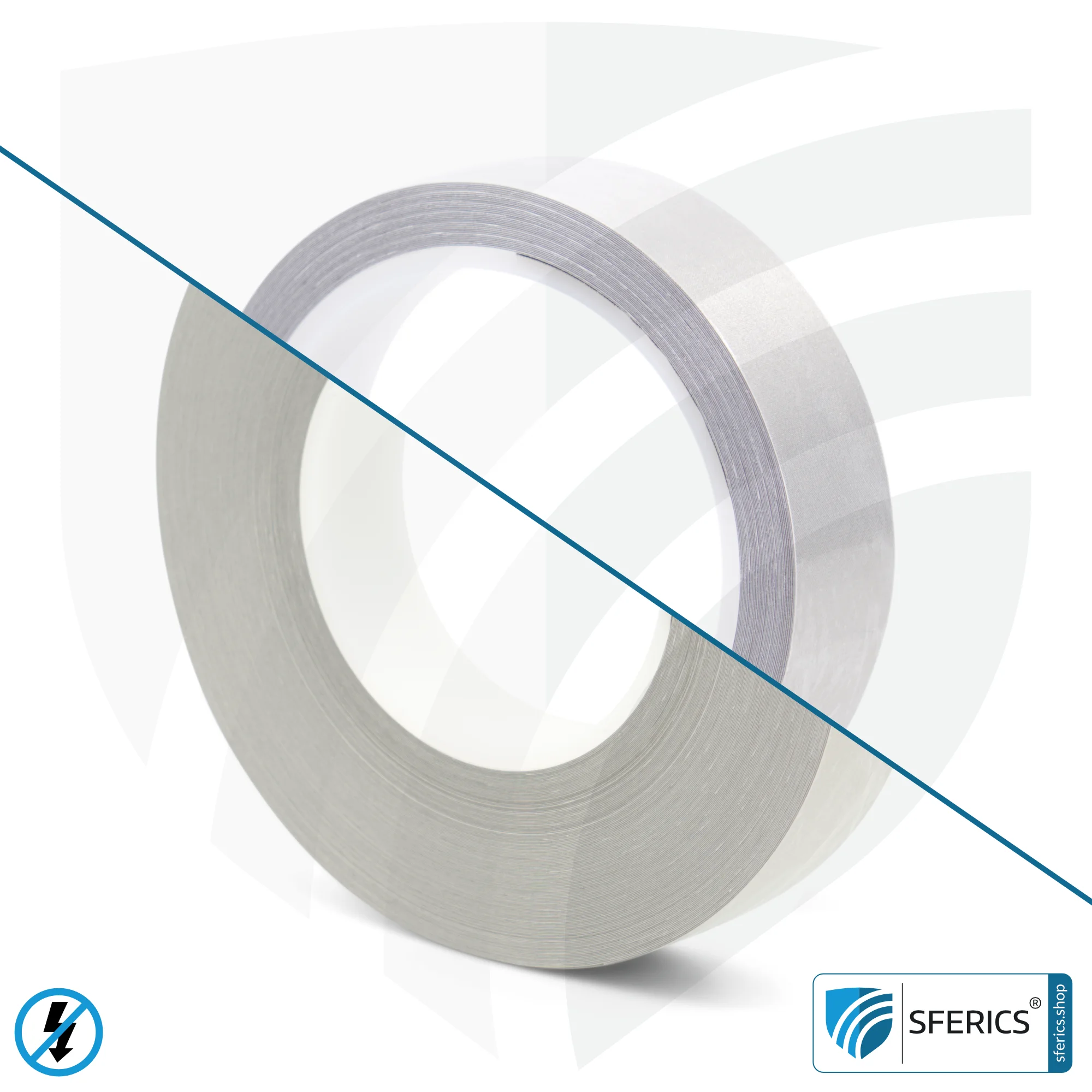

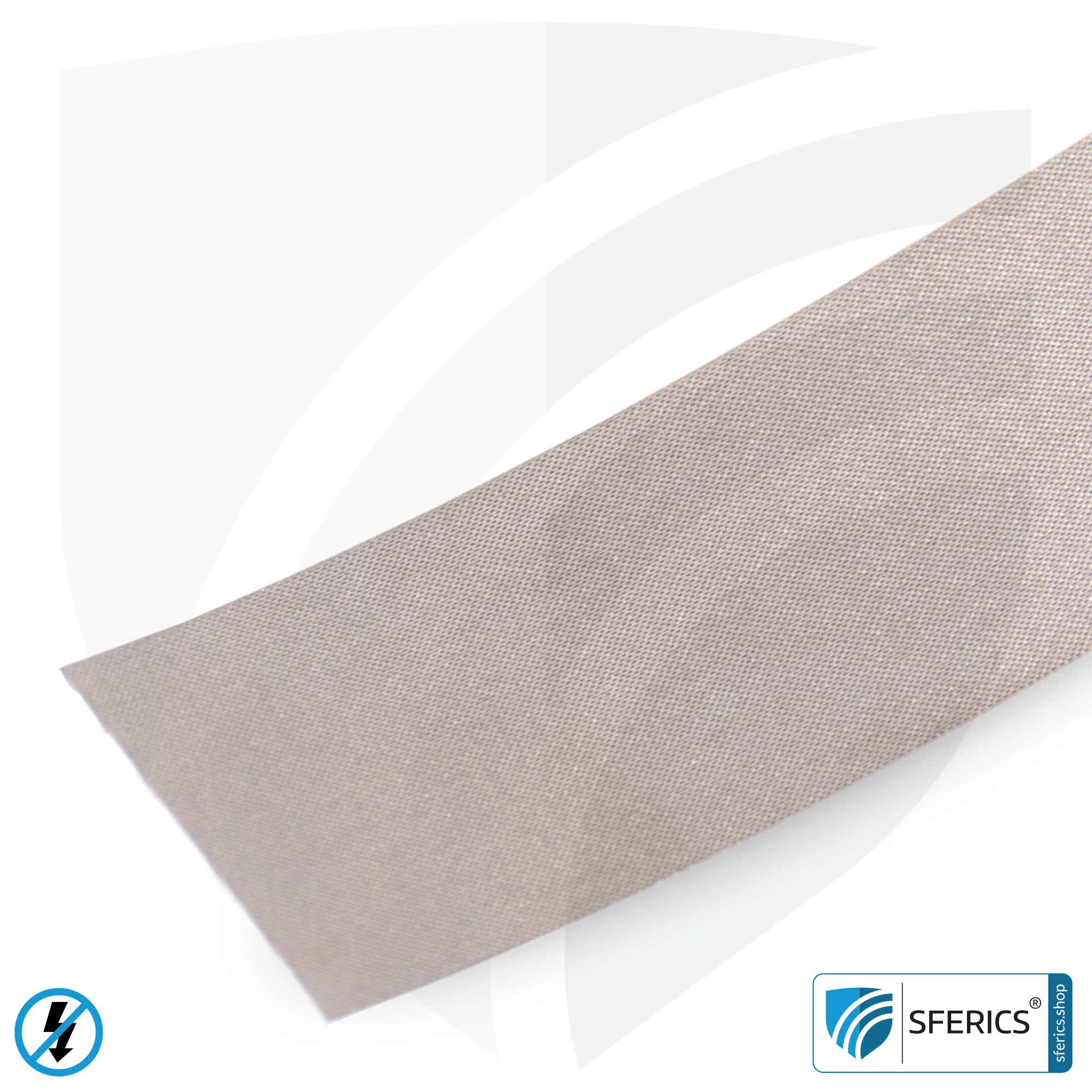

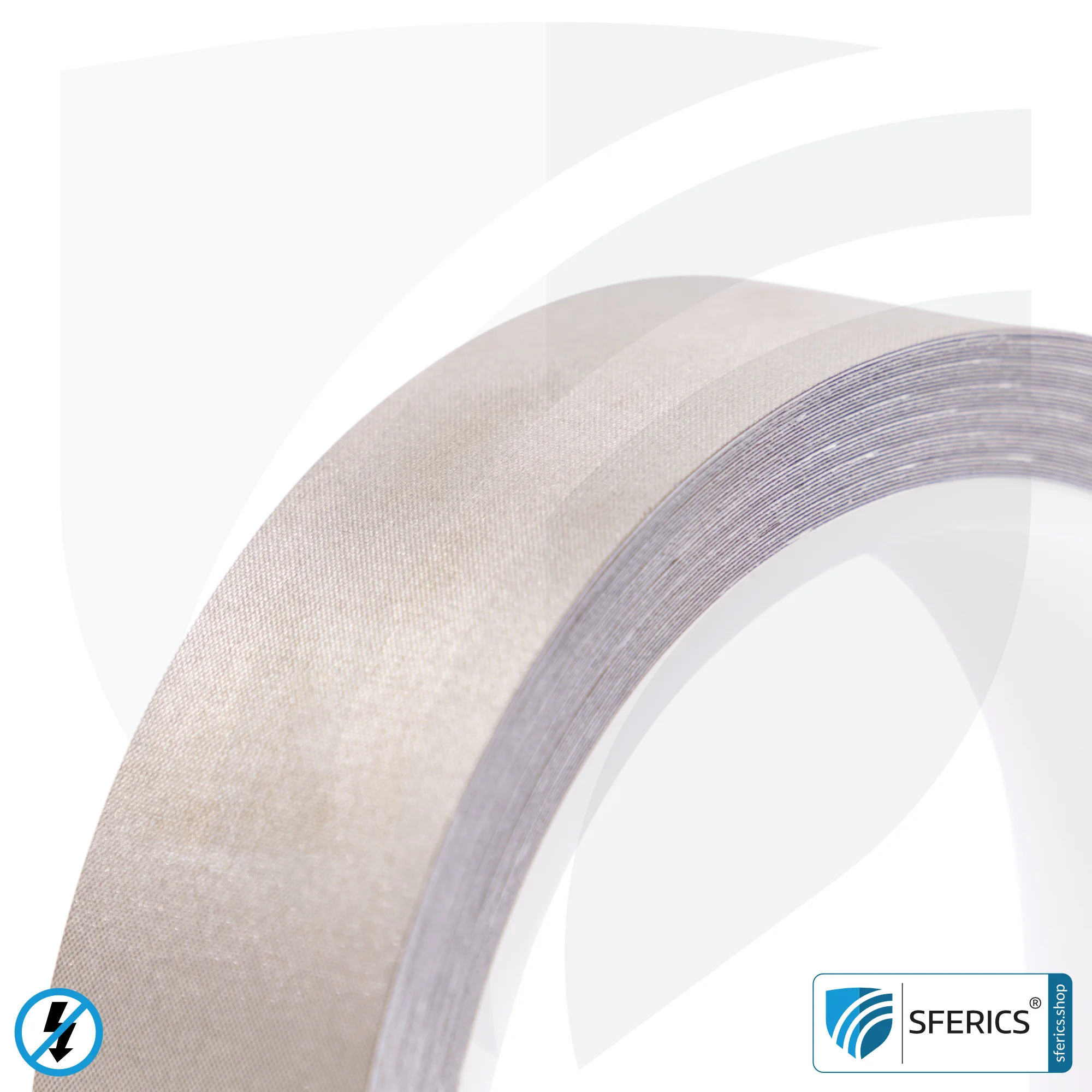

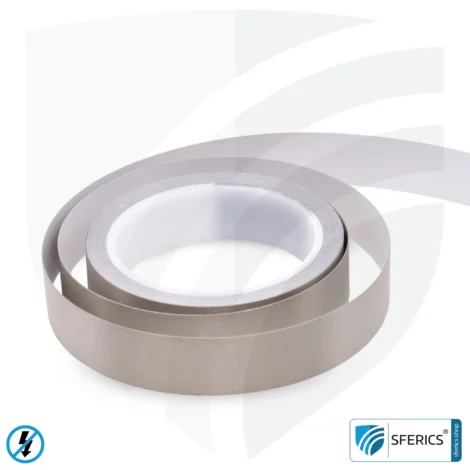

Shielding, self-adhesive grounding strap GSX with electrically conductive adhesive. Suitable for mounting (gluing) UNDER and ON shielding paints, shielding netting and shielding fleece. Based on our shielding fleece HNG80. Shielding effectiveness up to 80 dB. 2.5cm width.

Delivery time: approx. 1-3 working days

from: € 19,90

Grounding strap GSX, self-adhesive with electrically conductive adhesive for grounding electrically conductive surfaces. 2 lengths available: 10 meters and 50 meters.

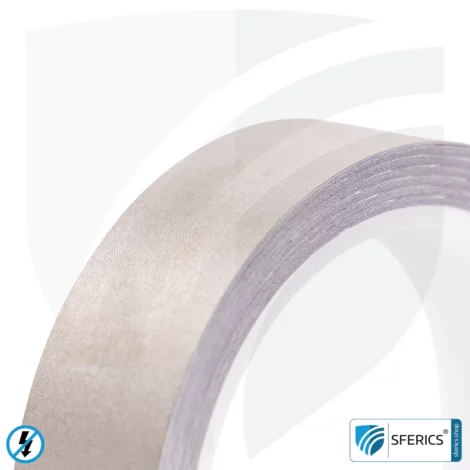

This grounding strap is based on our shielding netting HNG80 and was converted and extended to a conductive grounding strap by means of a self-adhesive, electrically conductive adhesive. By using HNG80 as a basis, the grounding strap has a shielding attenuation of 80 dB against high-frequency radio radiation in addition to the electrical conductivity. This makes this grounding band GSX suitable for use as a grounding band as well as for shielding small cracks and can effectively bridge them.

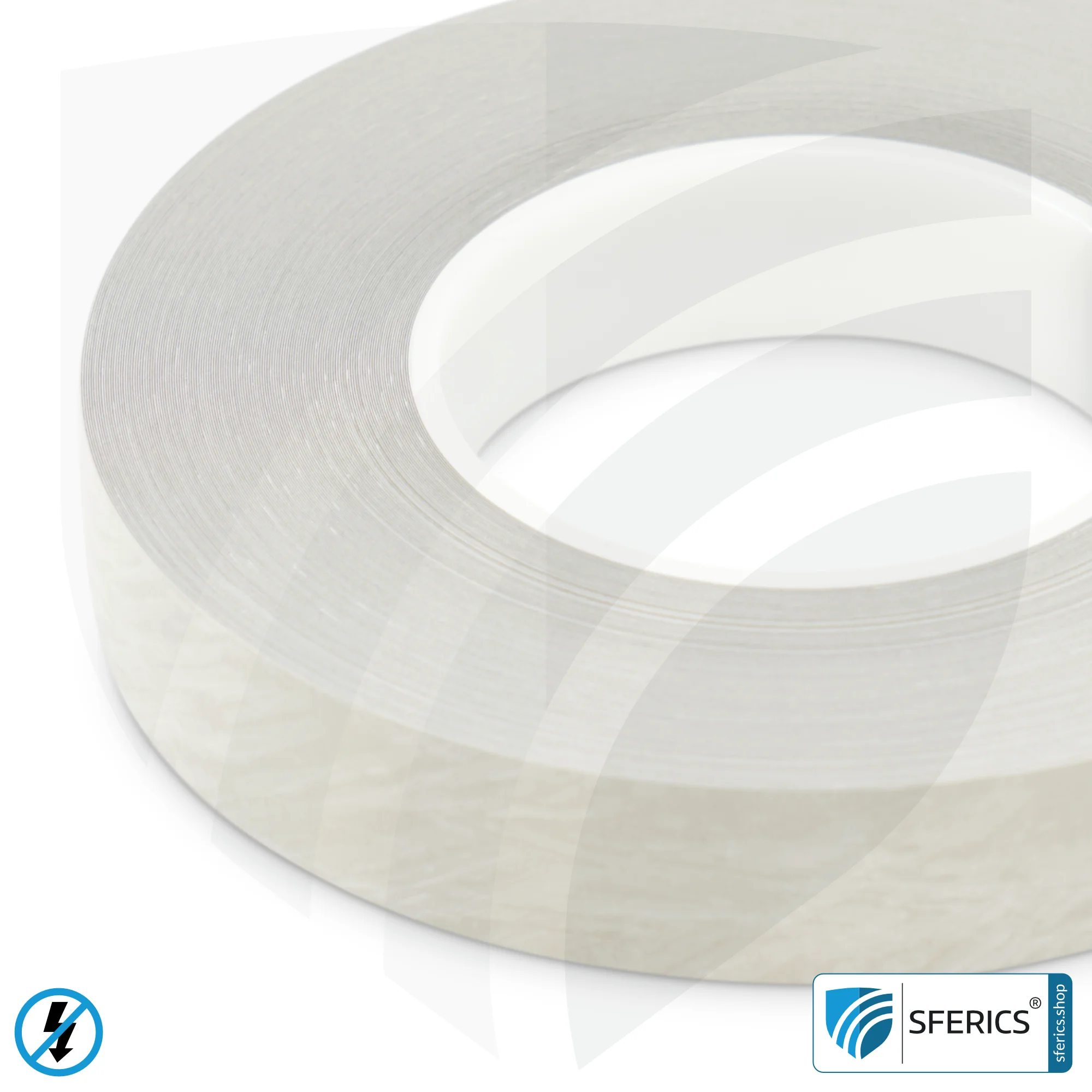

Due to the conductive adhesive, this grounding strap can be bonded both UNDER and ON shielding paints, shielding fabric or shielding fleece. Glues also on difficult surfaces. With only 0.11 mm extremely thin and invisible under shielding colors! For gluing we recommend our FVR10 plastic scraper.

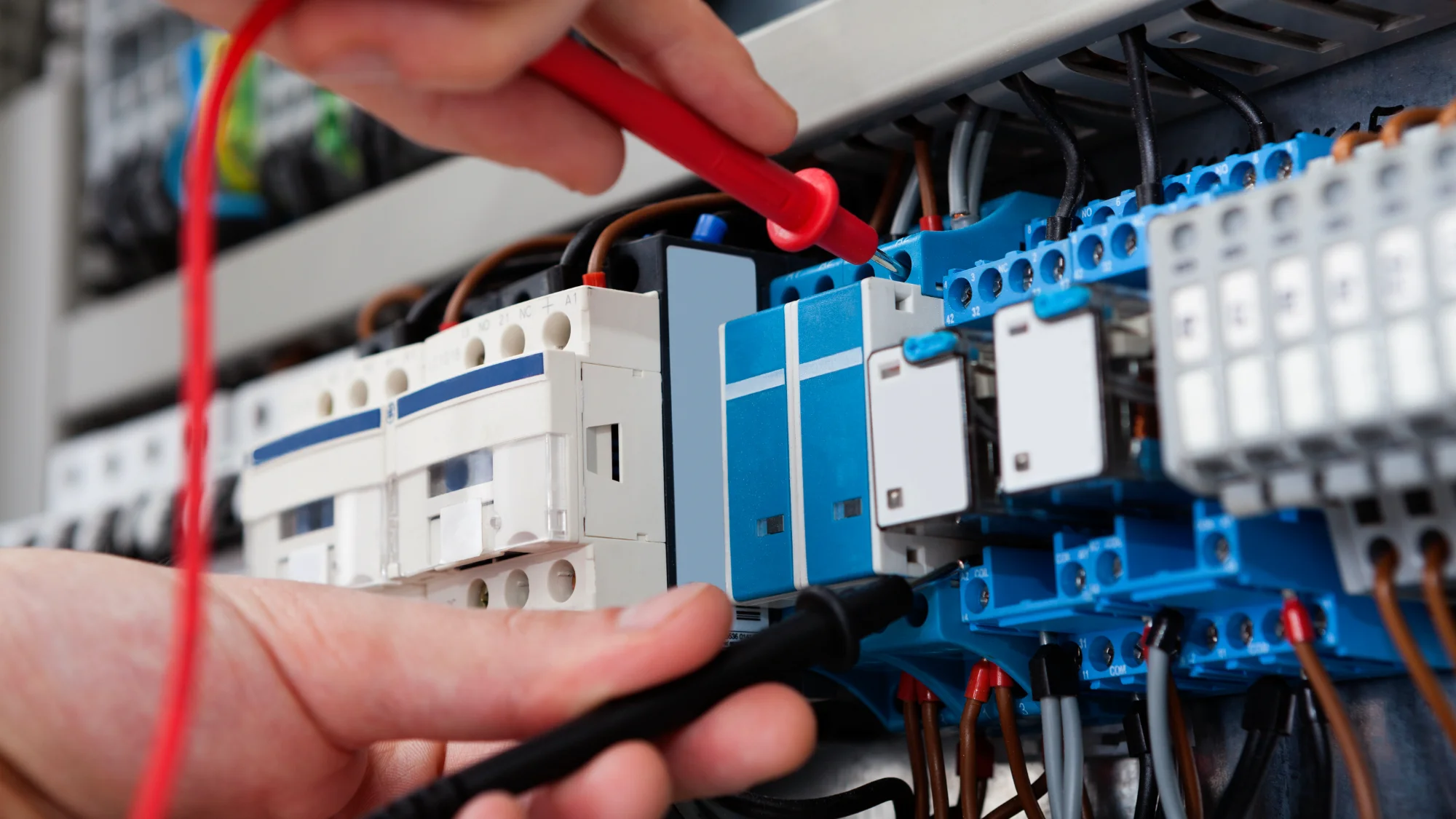

Grounding a Faraday cage is mandatory!

The grounding of a Faraday cage is imperative. This is also a legal requirement – an electrically conductive surface must be grounded for reasons of personal safety by law. This is about the mandatory potential equalization (up to the FI circuit breaker) which results from the “requirements for protection against electric shock” and is binding in a DIN VDE regulation.

Processing of self-adhesive ground strap GSX

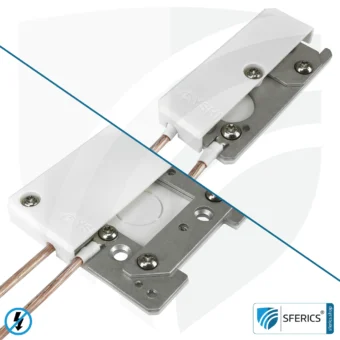

An electrically conductive grounding strap is an excellent way to electrically connect a shielded conductive surfaces and tracks. An alternative to the grounding strap is our additive AF3 which contains electrically conductive carbon fibers. The grounding strap is glued directly onto or under the processed shielding material for electrical contact. Due to the electrically conductive adhesive both is possible.

Details to shielded grounding strap GSX with conductive adhesive

- 2 variants: length 10m / length 50m

- Self-adhesive

- With electrically conductive adhesive

- shielding attenuation: 80dB at 1 GHz

- Width 25mm

- Thickness 0.11mm

- Corrosion resistant

- Materials: Polyester, copper, nickel. Backside conductive acrylic glue with high adhesive strength

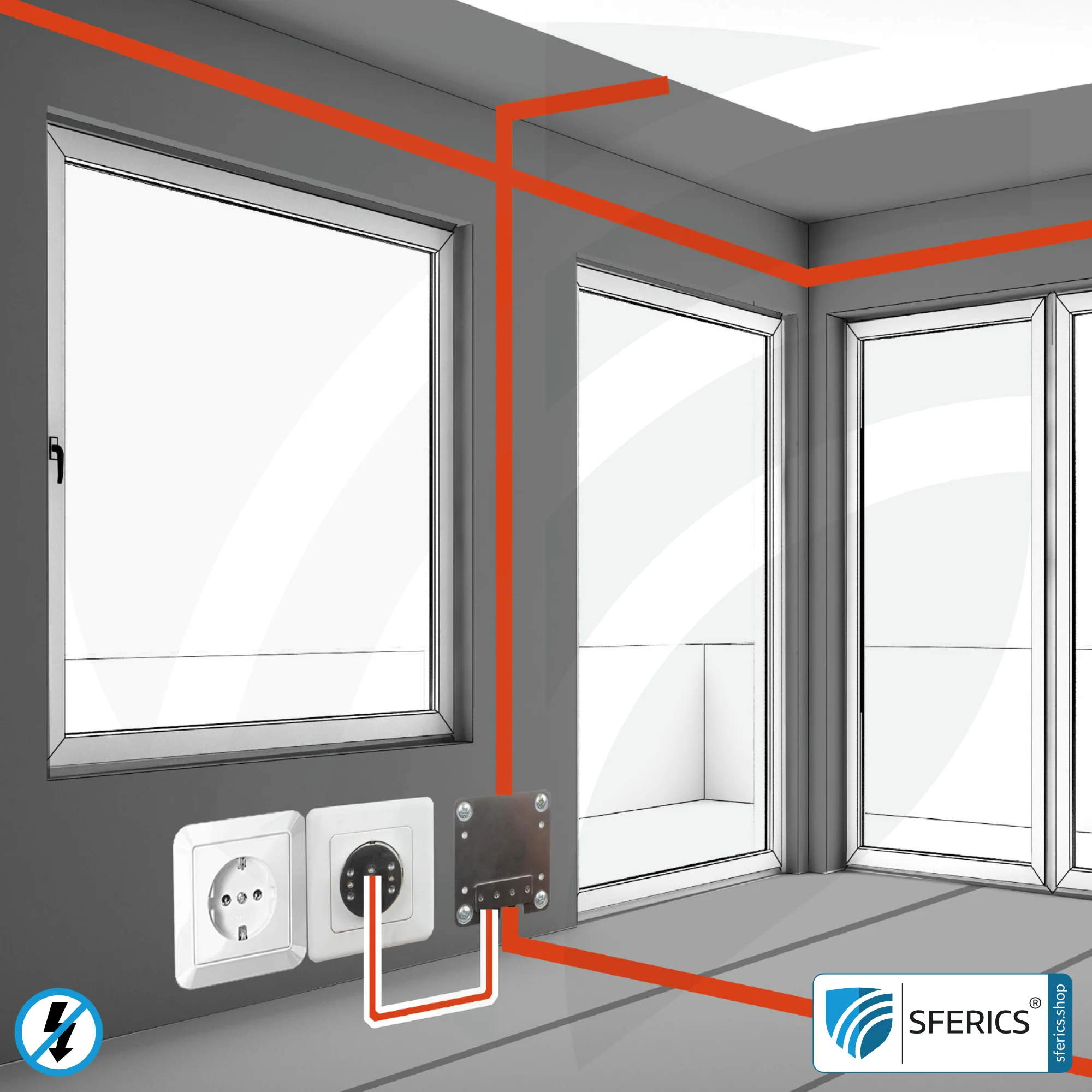

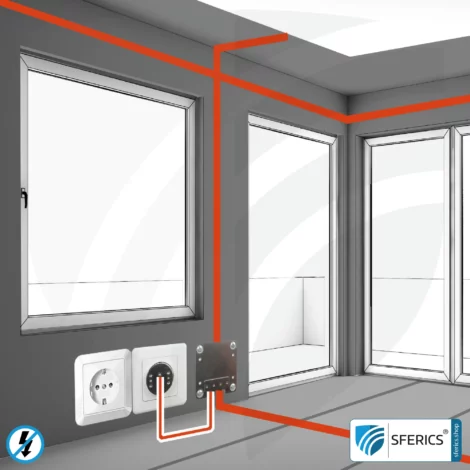

Schematic representation of grounding a room using GSX grounding strap

With the shielding paint, the grounding strap is glued between layer 1 and layer 2. For shielding fabric and shielding fleece after installation. Or first of all, before a shielding material is applied to the surface. Basically the grounding strap is laid in such a way that all surfaces are connected to each other. It is irrelevant whether this connection is made at the bottom of the floor or just below the ceiling.

All shielded surfaces are always grounded, in the predictive installation are the 6 sides – floor, ceiling and 4 walls. Simply put, the grounding strap is glued all around, so that all 4 walls are connected to each other. Then up to the ceiling and along one side of the ceiling. Then down to the ground and along one side of the floor area. In this simple way, all surfaces are electrically connected together and can be easily connected to the grounded outlet or grounded heating pipe.

This simple theory is usually more complex in practice, for example. Wall breaks, doors, windows, glued parquet floors, etc. In such cases it may be necessary to combine different grounding materials and shielding materials. Use our hotline for advice!

The connection to the earthing must be carried out by the electrician. We recommend checking the electrical installation and grounding. Grounding is only permitted in buildings with TN-S, TT and IT systems. The ground connection on a TN-C system is not possible or connected to a renewal of some parts of the electrical system. Under no circumstances may earthing be carried out in network forms with a combined PEN conductor!

More InformationBeware of unreasonable purchase of improper or incorrect use of this grounding straps!

Even if the health risk is rather low, ultimately it’s about nothing but your own safety and in the worst case of your own life. If, for example, a grounding strap is used with conventional industrial adhesive, it acts as an insulating instead of a connecting element, and thus the shielded area remains ungrounded if the grounding strap is used incorrectly and the shielded room can become life-threatening.

This is about the problem when drilling in the electrical line or a nail is hit. Without functioning grounding or equipotential bonding, the electrical current could spread to the entire shielded area via the shank of the drill or nail. Even if the chance for it is very small, it is assumed the highest possible risk. This would be at home current 220 V at 16 A on the wall, with power much more.

The life-threatening accident happens when touching the wall surface by an electric shock. Grounding or potential equalization of shielded, conductive surfaces prevents this.

Documentation (.pdf)

| Weight | N/A |

|---|---|

| Dimensions | 2,5 × 0,11 cm |

| Length | 10 meters, 50 meters |

| Color | metallic |

| Brand | |

| GTIN | 4260103665001, 4260103665018 |

| TARIC | 74102100 |

1 review for Grounding strap GSX, self-adhesive | grounding of shielding paint, shielding netting, shielding fleece, etc.

| 5 star | 0% | |

| 4 star | 100% | |

| 3 star | 0% | |

| 2 star | 0% | |

| 1 star | 0% |

Grounding strap GSX, self-adhesive | grounding of shielding paint, shielding netting, shielding fleece, etc.

Grounding strap GSX, self-adhesive | grounding of shielding paint, shielding netting, shielding fleece, etc.

Application tips and advice would be helpful!